11

Note

n

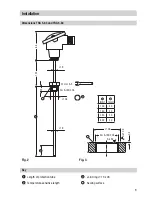

To install the temperature sensor in a pipe, weld the elbow

c

onto it. This ensures that

the temperature sensitive part

2

,

6

of the temperature sensor is immersed in the

fluid against the flow direction

Fig. 7 and Fig. 8

n

Install the temperature sensor such that the temperature-sensitive part

2

,

6

is

permanently immersed in the fluid.

Fig. 2 and Fig. 4

n

The seating surfaces of the threaded standpipe or the flange provided on the vessel

must be accurately machined, see

Fig. 3.

n

Do not completely insulate the temperature sensor. See examples of installation in

vessel

Fig. 5 and Fig. 6

n

Only qualified welders certified according to EN 287-1 may weld welding sleeves into

lines or vessels.

Attention

Installation

TRG 5-63 and TRG 5-64

1. Check seating surfaces.

Fig. 3

2. Put joint ring

3

onto the sealing surface of the threaded standpipe or flange provided on the

vessel (select joint ring material according to the range of application).

Fig. 3

3. Screw in the temperature sensor and fasten it with an open-end spanner 27 mm A. F. The torque

required

when cold is 150 Nm.

TRG 5-65, TRG 5-66, TRG 5-67 and TRG 5-68

1. Provide a penetration for the socket-weld end on site.

2. Unscrew the upper part of the temperature sensor from the welding sleeve

5

.

3. Weld the welding sleeve

5

in place. Arc-weld the equipment in place, applying welding process

111 and 141 in accordance with ISO 4063.

4. Put copper ring onto welding sleeve

5

and screw the upper part of the temperature sensor into

the welding sleeve

5

. Fasten the upper part of the temperature sensor when cold with an open-

end spanner (17 or 24 mm A. F.).

Tools

n

Open-end spanner 17 mm A. F.

n

Open-end spanner 24 mm A. F.

n

Open-end spanner 27 mm A. F.

- continued -