22

5

.2

T

ROUB

LE

S

HOO

T

IN

G

M

a

c

hine

troub

le

Caus

e

S

olution

M

a

ch

ine

c

a

n

n

o

t

w

o

rk

P

o

wer su

p

p

ly fo

r

m

o

to

r i

s t

ri

p

p

e

d

S

cree

n

l

a

m

p

n

o

t

ON.

Fo

o

t

se

c

u

ri

ty

is b

rok

e

n

.

A

ctiva

te

th

e

p

o

w

e

r sw

itch

.

Che

ck m

icr

o

-

p

roce

sso

r b

o

a

rd

.

Rele

a

se

th

e

s

e

cu

ri

ty

s/

w

.

T

u

rnta

b

le

c

a

n

n

o

t t

u

rn

M

icr

o

p

roce

sso

r b

o

a

rd

b

roke

n

M

o

to

r sto

p

t

u

rni

n

g

Cha

n

g

e

m

icr

o

p

roce

ss

o

r b

o

a

rd

Che

ck e

rr

o

r

m

e

ssa

g

e

f

rom

in

v

e

rte

r a

n

d

re

fe

r t

o

T

u

rnta

b

le

c

a

n

n

o

t

S

to

p

a

t

h

o

m

e

p

o

sitio

n

.

T

u

rnta

b

le

p

roxim

ity

S

/W

is n

o

t

worki

n

g

.

Che

ck t

h

e

p

roxi

m

ity S

/W

se

n

se

.

If

it

is

n

o

p

ro

b

lem

a

d

just

th

e

se

n

sin

g

p

la

te

.

CARR

IA

GE

u

n

it ca

n

n

o

t

m

o

ve

.

M

icr

o

p

roce

sso

r b

o

a

rd

b

roke

n

M

o

to

r sto

p

t

u

rni

n

g

.

Cha

n

g

e

m

icr

o

p

roce

ss

o

r b

o

a

rd

1.

Che

ck t

h

e

p

roxi

m

ity S

/W

se

n

se

.

If

it

is

n

o

p

rob

le

m

a

d

just

t

h

e

s

e

n

sing

p

la

te.

2.

Che

ck t

h

e

t

o

p

a

n

d

b

o

tt

o

m

li

m

it.

4

.2

E

L

E

CT

RIC DIA

GR

A

M

(1

S

5

A

).(

1

S

6

)

A

s d

o

in

g

A

UT

O

RU

N t

h

e

CARR

IA

GE

u

n

it g

o

e

s

u

p

a

n

d

o

ve

r

th

e

p

a

cka

g

e

h

e

ig

h

t

P

h

o

to

e

y

e

g

e

ts

se

n

se

f

rom

a

n

o

th

e

r

m

a

te

ri

a

l

e

xce

p

t p

a

ck

a

g

e

.

P

h

o

to

se

n

so

r g

e

ts

se

n

se

f

ro

m

a

n

o

th

e

r l

igh

t

so

u

rce.

1.

M

o

ve

a

way

o

th

e

r

o

b

je

cts

A

vo

id

th

e

ligh

t

so

u

rce.

2

.

Che

ck

t

h

e

p

h

o

to

e

y

e

4

.2

E

L

E

CT

RIC DIA

GR

A

M

(1

S

7

)

A

s d

o

in

g

A

UT

O

RU

N b

u

t

CARR

IA

GE

ca

n

n

o

t

g

o

e

s u

p

.

1

.P

h

o

to

e

ye

b

roke

n

P

h

o

to

e

y

e

ca

n

n

o

t

se

n

s

e

a

b

lack

co

lor

p

a

cka

g

e

.

2

.

P

h

o

to

e

ye

b

roke

n

P

h

o

to

e

y

e

ca

n

n

o

t

se

n

s

e

a

p

a

cka

g

e

.

3

.

T

u

rnta

b

le

p

ro

xim

ity

se

n

so

r i

s n

o

t

worki

n

g

1

.

Cha

n

g

e

p

h

o

to

e

ye

.

A

vo

id

a

b

lack

c

o

lor p

a

cka

g

e

o

r u

s

e

m

a

n

u

a

l

o

p

e

rati

o

n

.

2

.

Che

ck

t

h

e

p

h

o

to

e

y

e

4

.2

E

L

E

CT

RIC DIA

GR

A

M

(

1

S

7

)

3

.

Che

ck

t

h

e

se

n

so

r

4

.2

E

L

E

CT

RIC DIA

GR

A

M

(1

S

7

A

)

Summary of Contents for GPPW-1500B

Page 6: ...4 2 2 MACHINE DIMENSION ...

Page 7: ...5 2 3 Machine Description ...

Page 11: ...9 3 3 OPERATION OF CONTROL PANEL ...

Page 19: ...17 ...

Page 20: ...18 ...

Page 22: ...20 ...

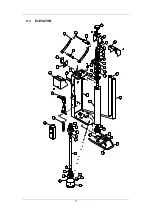

Page 25: ...23 6 PART LIST 6 1 SEAT 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 ...

Page 27: ...25 6 2 TOWER ...