38

ZONE 1

In case of production errors in zone 1 follow operations below to solve different situations.

Control, No nest in tub Pos.106

If tubs entering the system has a missing a nest or is damaged, an alarm notify the

operator.

To reset this alarm: Enter the zone, remove the tub in picking position 106. Go out of the

robot zone, reset safety and reset alarm on HMI.

ZONE 2

In case of production errors in zone 2, please follow the steps below to resolve the issues.

Timeout tub Pos. 225

In case of this alarm, the tubs have not been successfully inserted into the system. Check

if something is blocking any sensors or look downstream of system before restoring alarm

from HMI.

ZONE 3

In case of production errors in zone 3 follow operations below to resolve the issues.

Tub stack too close

If tub stacks are too close to each other in leaving or picking position on the buffering

conveyors an alarm will alert the operator.

To reset this alarm, you have to enter the system and physically ordinate and separate the

stacks, so that the sensors has a free sight.

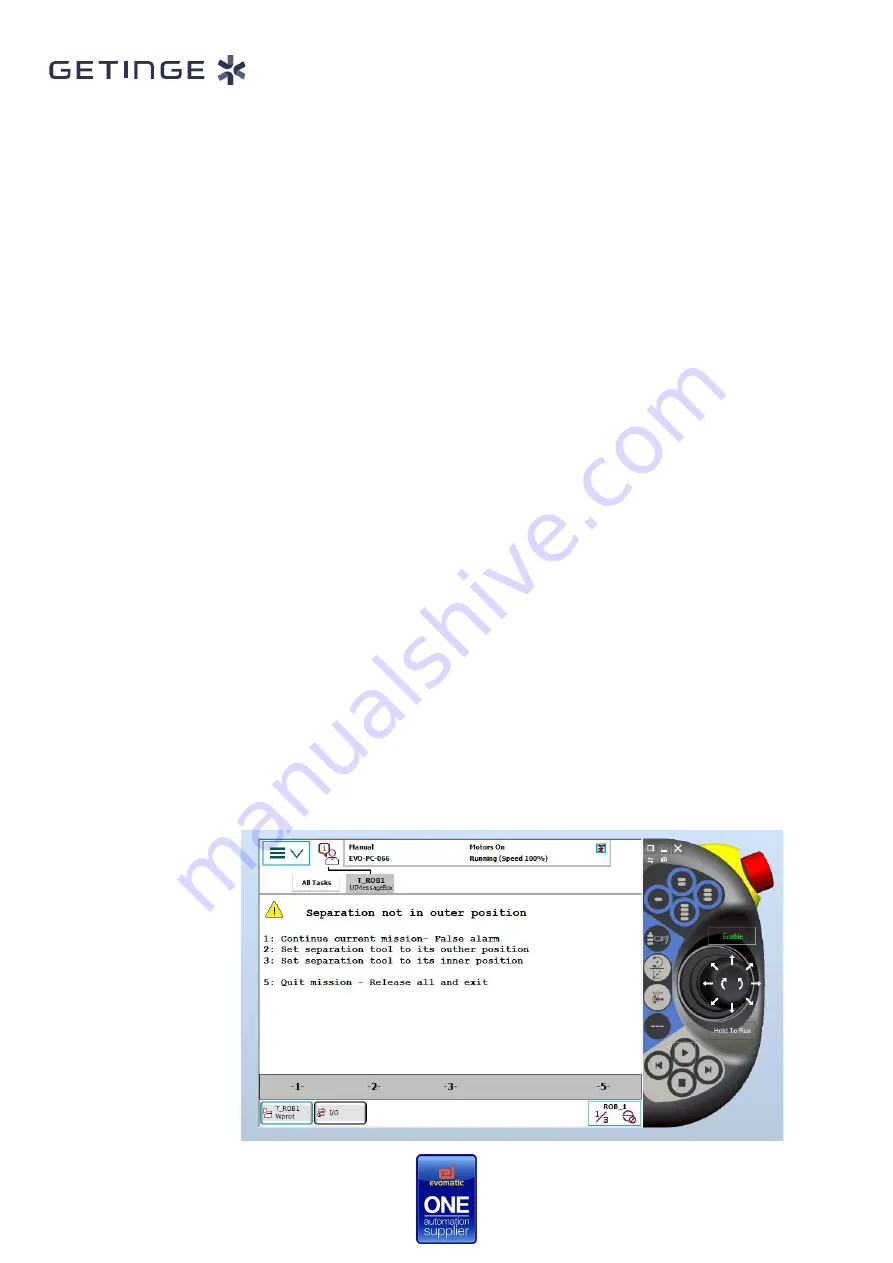

Robot 310 – Tub Handling – Buffer

Select option 2/4 to move the separation arms up/down to make sure they are not stuck.

Also check the sensors and adjust them if necessary.

Select 1 to continue without action, the program continues as expected.

Select 5 to exit ongoing mission, the robot will move to its home position.

Sensors to check: iSeparationIn & iSeparationOut

Summary of Contents for GEV TS 121650 AR-2

Page 1: ...1 GEV TS 121650 AR 2 PFIZER ROBOTIC SYSTEMS 0011393179 010 USER MANUAL...

Page 49: ...49 Robot pendant Manual Auto mode Auto Manual mode Quick menu Key selector...

Page 52: ...52 Quick select Jogging Increments Motion mode Step mode...

Page 54: ...54 Robot 210 Home position Robot 220 Home position...