IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

5

Safety notices

à

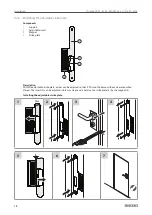

Remove the lock before drilling the fixing points for the sliding door fittings.

à

Do not put any greases, lubricants or oils in the lock. Avoid water penetrating the lockcase or the formation of

condensation.

à

Only use lubricants approved by GEZE for lubricating the outer parts (bolt, latch), see chapter 1.4.

à

Never paint or varnish over the lock face plate or any other parts of the locks.

à

Remove the lock before doing any painting work.

à

The handle pin must not be forced through the lock follower.

à

The door leaf must not be carried by the handle.

1.4 Cleaning and care

GEZE self-locking panic locks may only be oiled or greased using lubricants approved by GEZE.

Lubricant

Manufacturer

Comment

Klübersynth LI 44-22

Klüber Lubrication

Slightly wet the latch and bolt

Fin Lube TF

Interflon

Spray onto the latch and bolt from the

outside

1.5 Accessories

GEZE self-locking panic locks may only be used with the accessories prescribed by GEZE.

X

Only use genuine GEZE accessories.

à

If other parts are attached or installed, any warranty, guarantee and/or product liability claims will be ren-

dered invalid.

1.6 Assembly and installation

Some safety rules must always be observed during fitting and installation of the self-locking GEZE panic lock. These

must be noted and followed, since the device can otherwise be damaged and result in hazards for the user:

X

When installing the locks, make sure you following building regulations and any specifications issued by the

door manufacturer.

à

The lock must not be modified in any way.

à

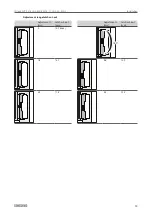

Lock and original strike plate (1-leaf) as well as lock and original strike box (2-leaf) form one unit. Perfect func-

tion is only possible in combination.

à

If installation is faulty or improper, all manufacturer guarantee and liability claims will be rendered invalid.

1.7 Use of motor locks IQ lock EL/IQ lock EL DL on fire and smoke protection doors

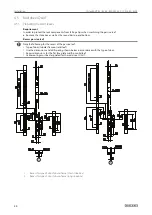

GEZE motor locks, IQ lock EL for 1-leaf and IQ lock EL DL for 2-leaf fire and smoke protection doors may be used

in all modes of operation (permanently unlocked, secured by day, night).

It must be guaranteed that in the event of a fire in the case of the modes of operation “permanently unlocked”

and “secured by day” the electrical activation of the lock is no longer possible, the lock can no longer be un-

locked and the cross latch and bolt engage securely in the locking plate at all times.

In order to interrupt this electrical activation in case of a fire, permissible fire alarms with trigger mechanisms, in

accordance with the DIBt Directive, must be employed for hold-open systems.

When motor locks are used on fire and smoke protection doors, three different installation situations can occur.

The following chapters must be heeded in this case.

1.7.1 Triggering via on-site fire alarm system

Connection of an on-site fire alarm system (BMA) to the motor lock control (MST 210).

This connection is implemented via the “smoke detector” input especially provided. A zero-potential or non-iso-

lated contact is required by the BMA for this.

The planning of the installation of the smoke detectors is implemented on site. It should be pointed out that

when motor locks are used, smoke detectors in accordance with the above-mentioned directive must be fitted.

Smoke development on both sides of the door must be detected by the BMA.