IQ lock AUT, EL / EL DL, EM / EM DL, C / C DL, M / M DL

11

Technical data

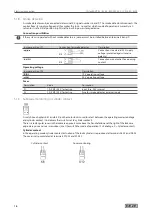

4.5 Power supply NT DR-30-24

ID No.

151425

Function:

Power supply for IQ AUT

Dimensions:

78 × 93 × 56 mm (W × H × D)

Operating voltage:

à

Primary: 230 V AC (±15 %); 480 mA; 50 Hz

à

Secondary: 24 V DC; 1.5 A; 36 W

Environmental conditions:

à

Service temperature: –20 … +60 °C

à

REL: humidity 20 … 90%

Installation:

à

Fixing to top hat rail DIN TS-35 / 7.5 or 15 possible

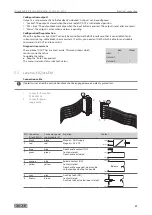

4.6 Power supply NT 2.5 A-24 V HS

ID No.

151424

Function:

Power supply for several components

Dimensions:

78 × 93 × 56 mm (W × H × D)

Supply voltage:

230 V

Power:

60 W

Output voltage:

21.6 … 26.4 V DC ±1% adjustable

Output current:

2.5 A

Connection:

Screw terminals 2.5 mm2

Service temperature:

-10 … +50 °C

Version:

Top hat rail casing

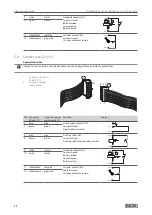

4.7 Motor lock control MST 210

X

Follow the mechanical installation instructions for motor lock IQ lock.

ID No.

103671

Function

Control unit for motor lock IQ lock EL / IQ lock EL DL

Dimensions

140 × 140 × 79 mm (W × H × D)

Weight

0.3 kg.

Operating voltage

12–24 V DC (–10%, +15%)

Current consumption

à

160 mA at 12 V DC

à

max. 1 A briefly at 12 V DC

à

80 mA at 24 V DC

à

max. 500 mA briefly at 24 V DC (incl. IQ lock)

Terminals

Plug/screw terminals, max. cable cross-section 1 mm²

Max. contact rating of the relays (X2)

30 V DC / 1 A

Max. lock switch contact load (X3)

30 V DC / 500 mA

Max. length of connection cable to the lock 10 m

IP rating in accordance with DIN 40050

IP54

Environmental conditions in accordance

with DIN 40040

à

Service temperature: JWF (–10…+50°C, max. 75% rel. hum.,

no condensation)

à

Storage temperature: HPE (–25…+85°C, max. 95 % rel. hum.,

no condensation)

Summary of Contents for IQ lock AUT

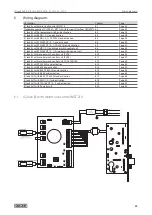

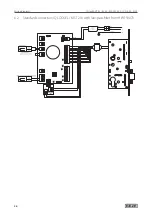

Page 56: ...IQ lock AUT EL EL DL EM EM DL C C DL M M DL 56 Wiring diagrams ...

Page 66: ...IQ lock AUT EL EL DL EM EM DL C C DL M M DL 66 Annex ...

Page 68: ...IQ lock AUT EL EL DL EM EM DL C C DL M M DL 68 Annex ...

Page 70: ...IQ lock AUT EL EL DL EM EM DL C C DL M M DL 70 Annex ...

Page 71: ...IQ lock AUT EL EL DL EM EM DL C C DL M M DL 71 Annex ...