5

Signet 3719 pH/ORP Wet-Tap

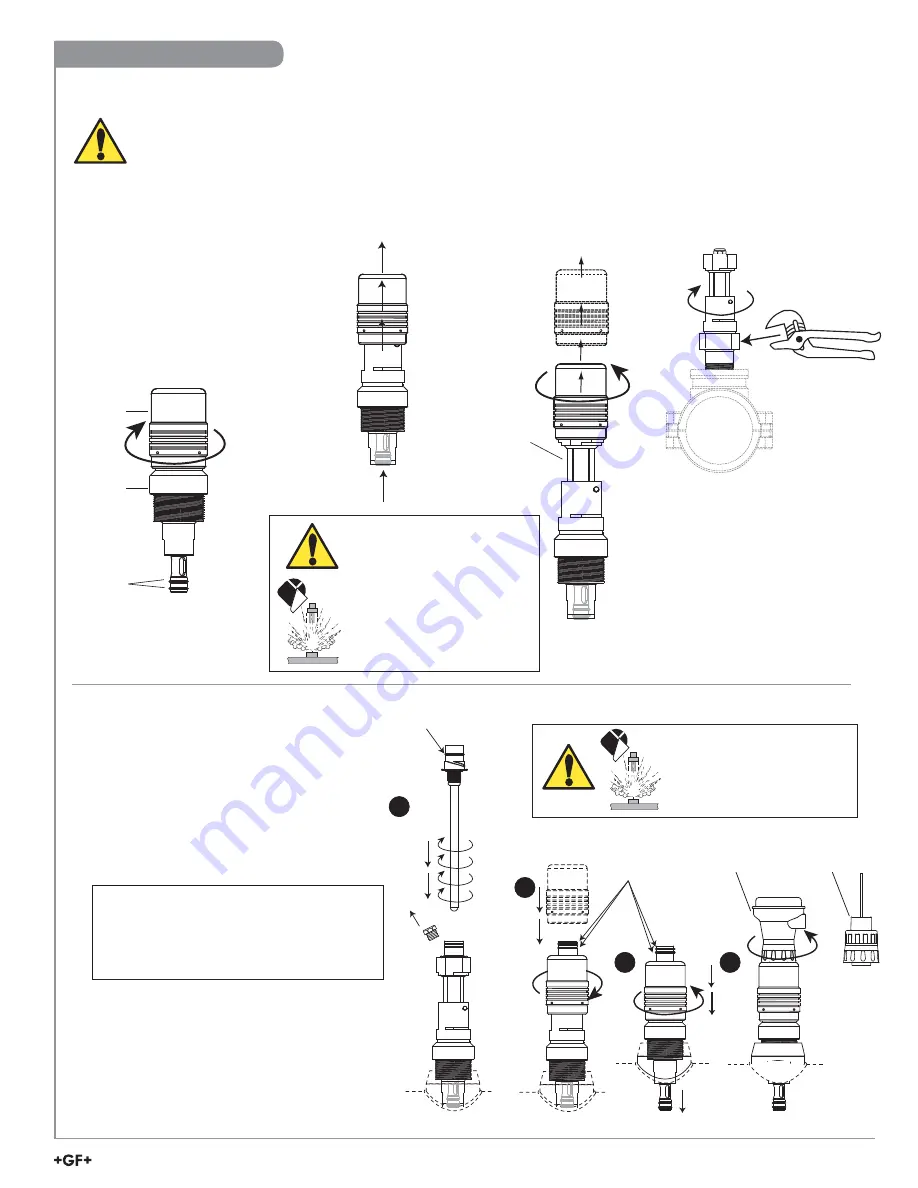

Pull the locking

shroud straight

up until both

O-rings are fully

seated inside

the retraction

housing.

Grasp the retraction

housing below the

locking shroud; turn the

locking shroud

1

/

4

-turn

clockwise.

1

2

The 3719 is packaged with no electrode installed, and with the electrode piston in the fully inserted position.

•

Examine the female threads at the top of the electrode piston. Do not install electrode if threads are damaged.

•

Examine the two O-rings at the lower end of the assembly. Do not install if O-rings are missing or there are any signs

of damage.

•

Lubricate O-rings with a non-petroleum based, viscous lubricant (grease) compatible with the system.

•

The pipe can be pressurized after completion of step 4.

•

DO NOT ATTEMPT TO REMOVE THE RETRACTION HOUSING FROM A PRESSURIZED PIPING SYSTEM!

Installation (Wet-Tap Into Fitting)

Lubricated

O-rings

Locking

Shroud

Retraction

Housing

Turn the

shroud

1

/

4

-turn

counterclockwise

and lift it

completely away

from the electrode

piston.

•

Thread the Wet-Tap into the

pipe

fi

tting.

•

Smaller pipes may require

bracing to support the Wet-Tap

weight and the longitudinal

forces required for operation.

•

Use an appropriate thread

sealant to prevent leaks.

•

The piping system can now be

safely pressurized.

•

Inspect the installation for leaks.

3

4

The electrode piston is locked

in position by SS locking pins.

DO NOT tamper with the

locking pins!

If the piston is depressed with

no electrode installed, the pipe

contents are exposed.

Electrode

Piston

Electrode Installation

Before installation, lubricate O-rings with a non-

petroleum based, viscous lubricant (grease)

compatible with the system.

1. Remove the safety plug from top of electrode

piston. Slide electrode straight down into

electrode piston. Thread electrode into place

until connector shoulder is

fl

ush with top of

electrode piston. Hand tighten only.

WARNING:

Do not

fl

ex the electrode when inserting

into the Wet-Tap assembly. The electrode can

be permanently damaged if it is

fl

exed during

installation.

2. Place the Locking Shroud over electrode; turn

¼-turn clockwise to unlock the piston, then press

down

fi

rmly on the locking shroud to lower the

electrode piston into the pipe.

3. Turn the shroud

1

/

4

-turn counterclockwise to lock

the piston.

4. Install the matching electronics assembly or

preampli

fi

er onto the electrode connector.

DO NOT ATTEMPT TO

REMOVE THE RETRACTION

HOUSING FROM A

PRESSURIZED PIPING

SYSTEM!

Installation continued

1

2

3

4

OR

Lubricate O-Rings

Lubricate O-Rings

2750

2760