6

Pos: null /BA_Module/BA_GA Mechanische Montage/BAGA006603_M001 @ 0\mod_1273581431158_28.docx @ 528695 @ 1 @ 1

3

Mechanical installation

Prerequisites

The permissible loads on walls, fastenings, mountings and transmission elements must not

be exceeded, even for maximum holding torques or locking torques (▶ refer to technical

data).

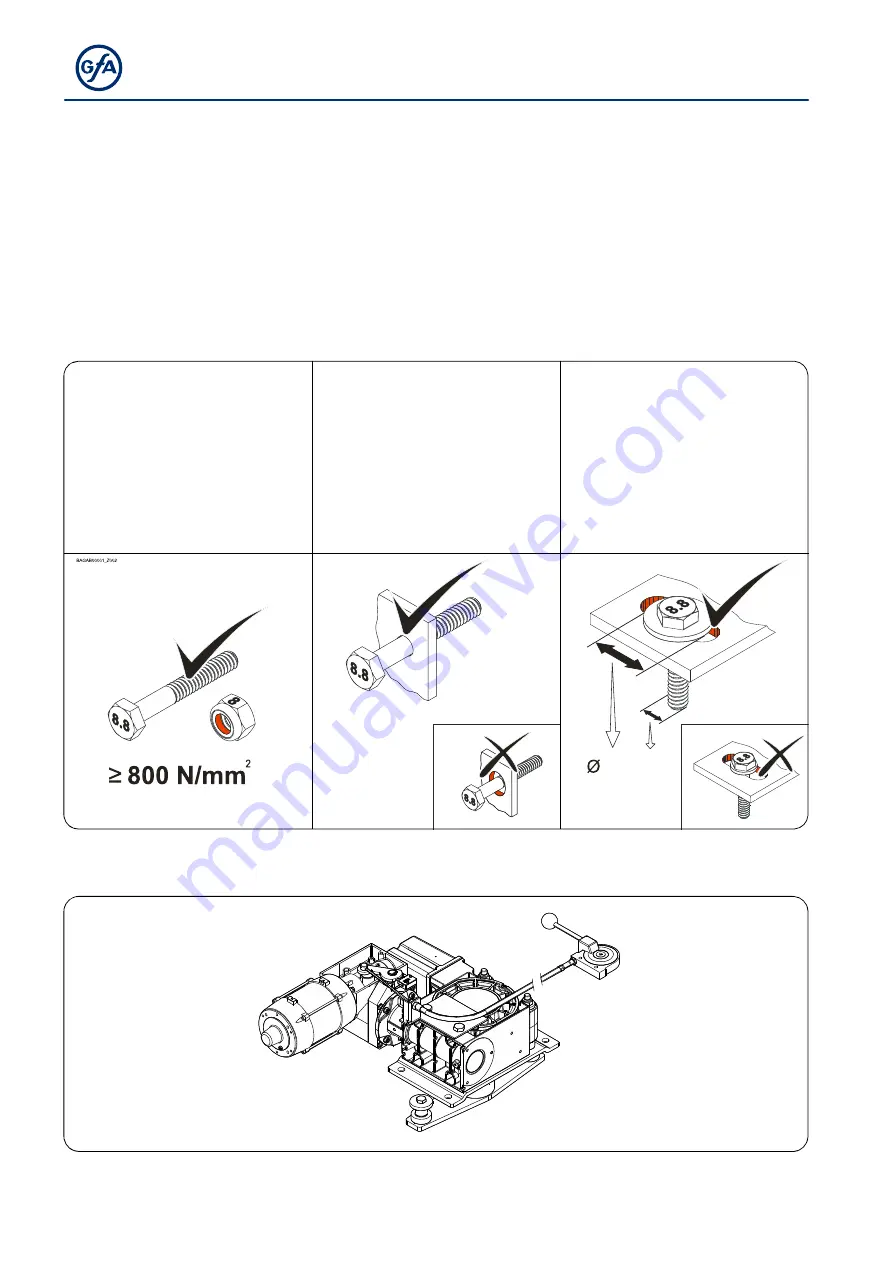

Connection elements

▶

Self-locking connection

elements with a minimum

strength of 800 N/mm

2

(8.8) must be used.

▶

Utilize the hole diameter

to the full.

▶

Use adequately

dimensioned washers for

elongated holes.

BAGAB00002_Z002

BAGAB00003_Z002

3 : 1

Permissible mounting positions

BAGAC06401_Z001