Display Cases / Plug-in

8

www.ggmgastro.com

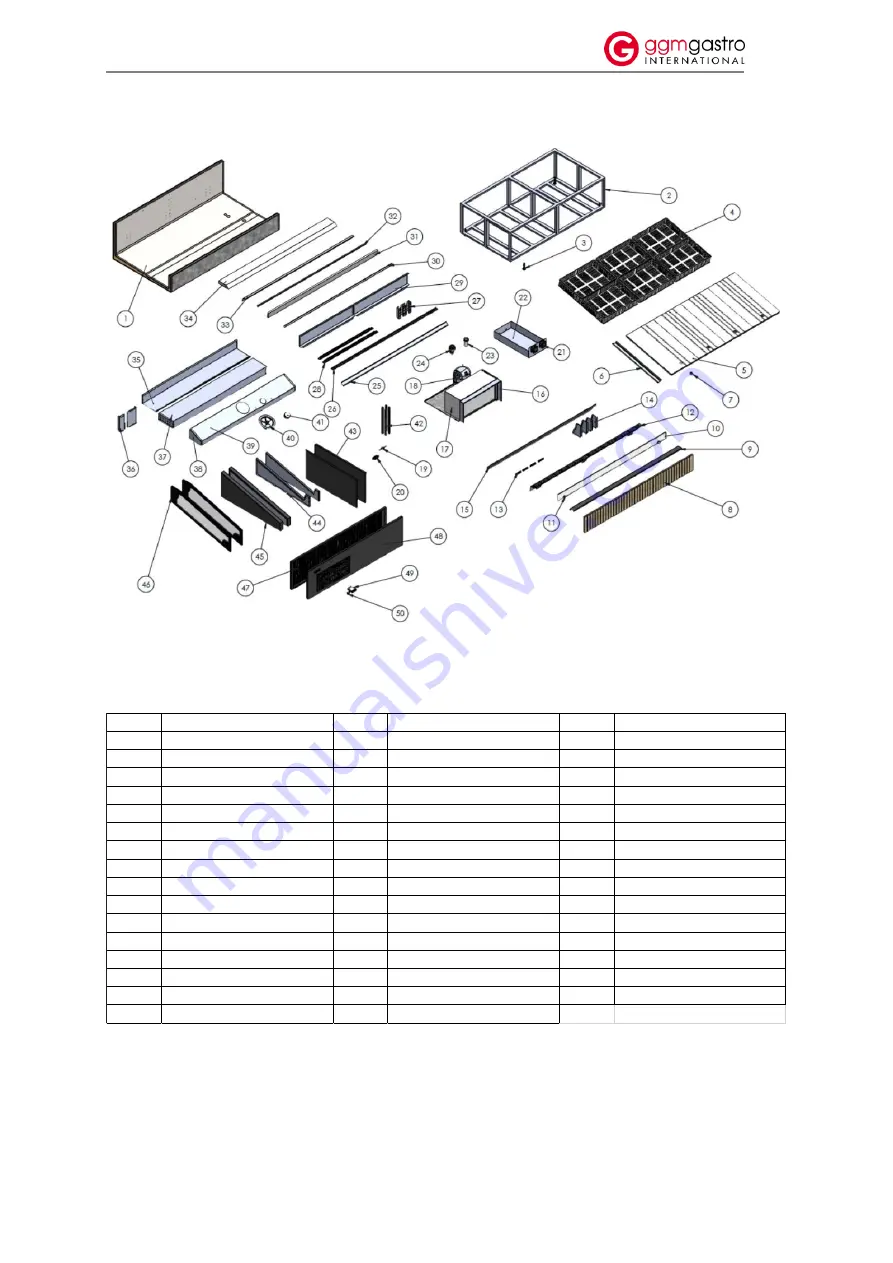

6.PART LIST

1

Polyurethane Panel

18

Compressor

35

Evaporator Top Sheet

2

Chasis

19

Sight Glass

36

Bypass Sheet

3

Adjustable Feet

20

Dryer

37

Evaporator

4

Plastic Basket

21

Square Fan

38

Evaporatör Side Sheet

5

Tray

22

Evaporating Box

39

Fan Plate

6

Tray Support Sheet

23

Pipe Cover Plastic

40

Fan Set

7

Tray Plastic

24

Drain Kit

41

Junction Box

8

Front Furniture

25

Bottom Air Baffle

42

Shutter Kit

9

Front Plating Sheet

26

Rear Bottom Sheet

43

Chassis Side Sheet

10

Front Glass

27

Rear Blowing Kit

44

Side Panel Sheet

11

Glass Holding Kit

28

Rear Top Sheet

45

Side Panel

12

Front Suction Sheet

29

Rear Blowing Sheet

46

Side Panoramic Glass

13

Front Suction Locking Sheet

30

Honey Comb Rear Bottom Sheet

47

Rear Shutter Sheet

14

Front Suction Support Sheet

31

Honey Comb

48

Front Shutter Sheet

15

Suction Under Z Sheet

32

Honey Comb L Sheet

49

Digital Thermostat

16

Condenser Bypass Sheet

33

Air Baffle Sheet

50

Switch

17

Condenser

34

Top Sheet