EN

EN-5

1.1 INTRODUCTION

DANGER:

Before using the machine, carefully read the

attached “

SAFETY WARNINGS FOR THE

FLOOR SCRUBBER DRYER

” manual.

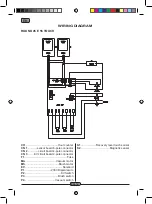

2.1 GETTING TO KNOW

THE MACHINE (Fig. 1)

1) Guide handle.

2) Control console.

3) Squeegee activation lever.

4) Water supply tap.

5) Solution tank.

6) Tank cover.

7) Clean water filling opening.

8) Wheels.

9) Removable splash guard.

10) Brush.

11) Squeegee.

12) Recovery water drain hose.

13) Squeegee water aspiration hose.

14) Recovery water tank.

15) Clean water drain/level tube.

16) Electric connection plug.

17) Clean water filter.

18) Brush up/down pedal.

19) Brush rotation activation button.

20) Touch sensor for the start-up and rota-

tion of the brush.

3.1 UNPACKING (Figg. 1-2)

Once the packaging has been removed as

shown in the instructions on the packaging it-

self, check that the machine and all the com-

ponents supplied are intact.

If any evident damage is found, contact the

area agent and the carrier within 3 days of

receipt.

- Remove the bag (21) containing the ac-

cessories.

- Cut the strap (22).

- Remove the wooden blocks (23 and 24).

- Lift the brush flange (9) by pressing down

on the pedal (19) (see relative para-

graph).

- Lift the wiper support (25) by lifting the

handle (3 Fig. 1) (see relative paragraph).

- Position a chute and unload the machine

from the bench.

3.1.a - Standard machine equipment

(Fig. 3)

The accessories supplied are as follows:

10) Brush/brushes.

11) Wiper.

26) Water filling hose.

27) Machine use and maintenance manual.

28) Anti-tear hook.

29) Fuses.

30) Filter for clean water tank opening.

4.1 ASSEMBLING THE

COMPONENTS

4.1.a - Wiper assembly (Fig. 4)

- Loosen the two handwheels (31) located

on the wiper (11).

- Assemble the wiper (11) on the support

(25), tightening the two handwheels (31).

- Connect the tube (13) to the wiper con-

nector (32).

N.B.:

Perform the previous operations with the

wiper support lowered.

4.1.b - Brush assembly (Fig. 5)

HAZARD:

Operation to be performed by two people!

- Raise the splash guard (9) and remove

the polystyrene protection (33).

- Assemble the brush as described in the

paragraph “replacing the brush”.

Accessories

0.7 ø PPL brush

40.0003.00 POLY 0,7

Brush spray guard

24.0265.00 + 40.4003.00

Front rubber wiper element

39.0110.00

Rear rubber wiper element

39.0111.00

Water loading tube

30.0024.00

Cable extension 25m

34.0427.00

Optional accessories

0.9 ø PPL strong brush

40.0103.00 POLY 0,9

1.2 ø PPL brush

40.0303.00

1.2 ø tynex brush

40.0203.00

Set polyurethane rubbers

95.0055.00

Drive mechanism

40.1003.00