Instruction Manual

KH Director®

EN

2018-02-19

23

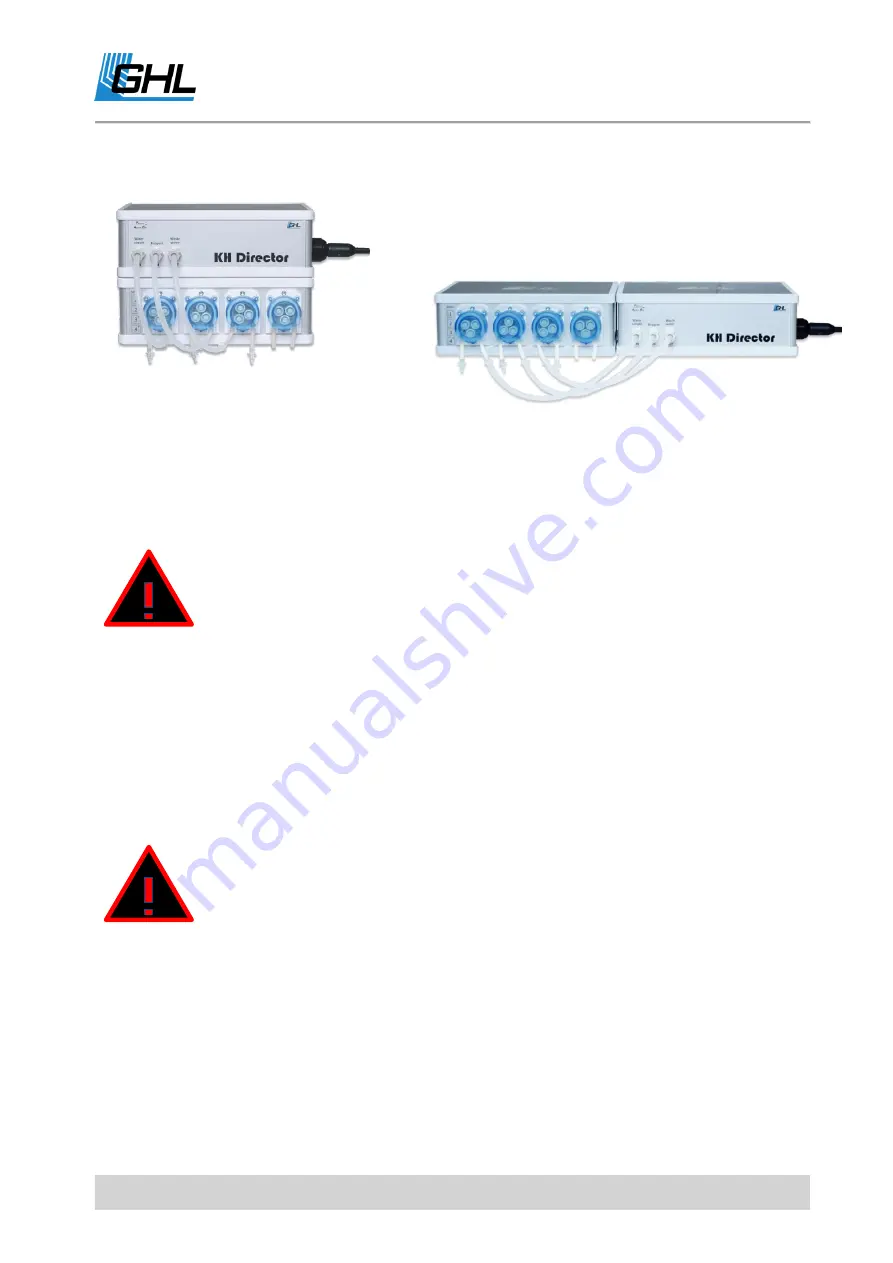

Assembly stacked and next to each other:

DANGER

•

Before activation, the connected reagent tube (pump 2) must be

completely deaerated.

•

Carefully perform the deaeration, as otherwise accurate

measurement results cannot be achieved.

•

Guide the reagent tube in a way that no air bubbles can form

during operation.

•

The venting of the internal reagent tube takes place shortly before

the measurement is carried out (see point 5).

DANGER

•

During operation, it must be ensured that no air bubbles can form

in the reagent tube, as these can falsify the measurement result.

•

The tube length to the reagent liquid must not exceed 50 cm /

19,69”

.

•

If you detect air in the tubes, deaerate them again and then vent

the internal reagent tubing using KH Director -> Maintenance ->

Vent internal reagent tube

.