HD2307

- 12 -

V1.7

C

ONNECTING THE

TP47

CONNECTOR FOR THE

3

AND

4

WIRE

P

T

100

AND

2

OR

4-

WIRE

P

T

1000

PROBES

:

Where present, extend the telescopic rod to the necessary length paying attention to

the cable so that All probes produced by Delta OHM are provided with a connector.

The Platinum Thermometer Model HD2307.0 also work with direct 3 and 4-wire

Pt100 and 2 or 4-wire Pt1000 probes manufactured by other producers; for the

instrument connection is prescribed the TP47 connector to which the probe's wires

should be welded.

The instructions to connect the Platinum probe to the TP47 module are provided

below.

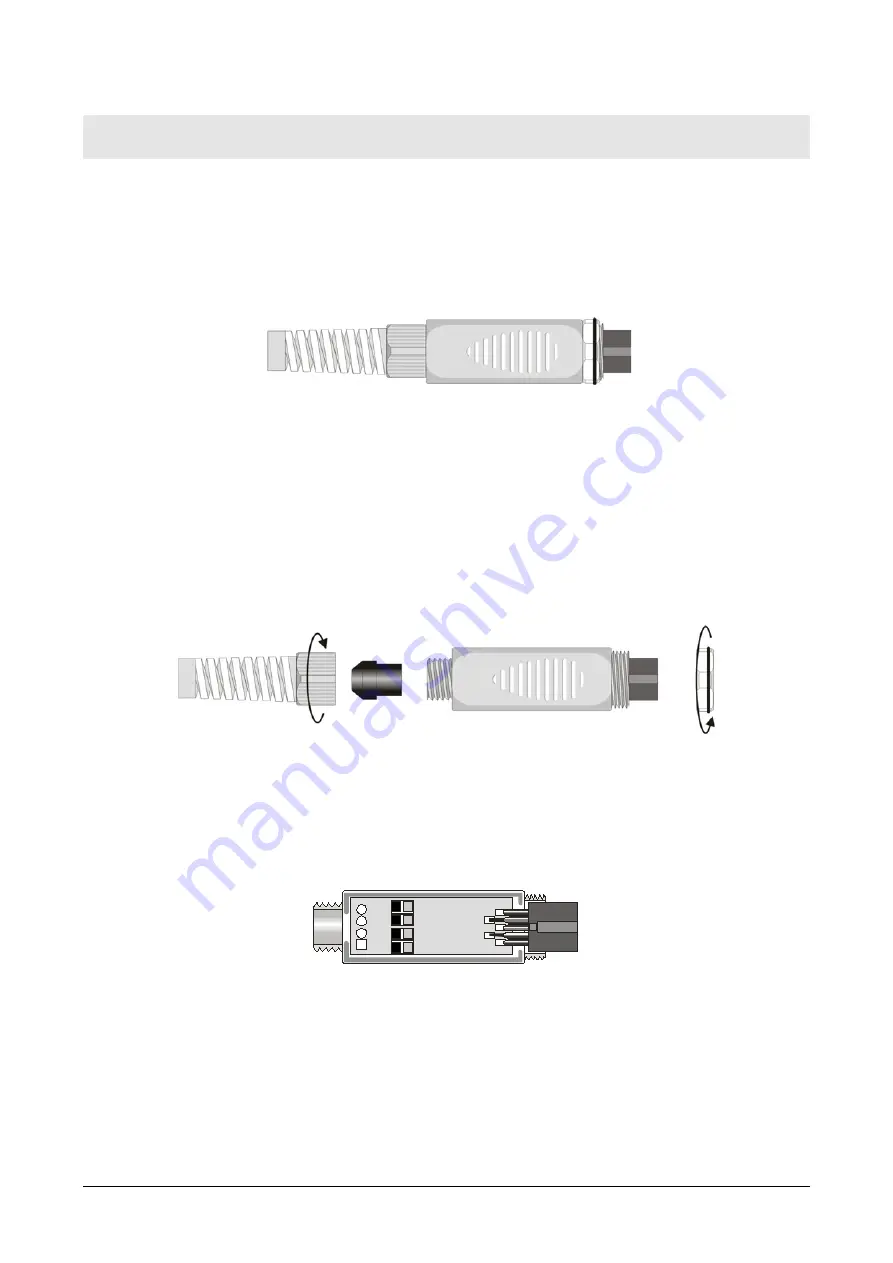

The TP47 module is supplied complete with fairlead and gasket for 5 mm maximum

diameter cables.

Do the following to open the module and connect a probe:

1.

unscrew the fairlead;

2.

extract the gasket;

3.

remove the label using a cutter;

4.

unscrew the ring on the opposite side as illustrated in the figure:

5.

open the two module shells: the printed circuit to which the probe must be

connected is housed inside. On the left there are the 1…4 points on which the

sensor wires must be welded. The JP1…JP4 jumpers are in the center of the board.

These must be closed with a tin bead for some type of sensors:

1

2

3

4

Pt100 3 wires

Pt1000

Ni1000

Not Used

Caution! Before welding, pass the probe cable through the fairlead and gasket.

Summary of Contents for Delta OHM HD2307.0

Page 4: ...HD2307 4 V1 7 RTD Thermometer HD2307 0 ...

Page 23: ......