G 1700 series

5 | Measurement Basics

B-H86.0.0X.DK2-3.1

13 / 20

5

Measurement Basics

5.1

Sensor/device accuracy

The device can be equipped with different interchangeable sensors. The temperature

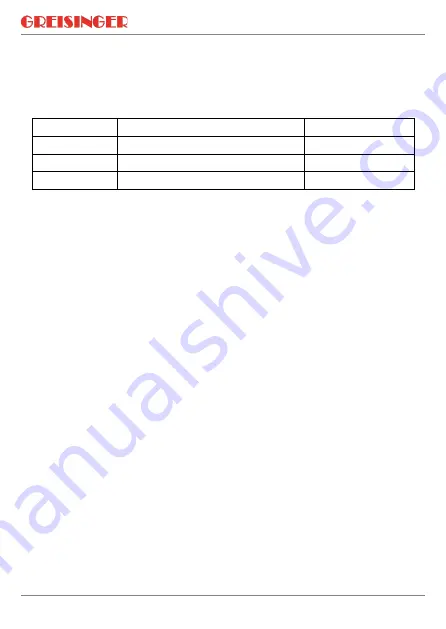

sensors are divided into the following classes according to EN 60751.

class

deviation

temperature range

B

±0,3 °C ±0,5 % of measured value

-

50 … +500 °C

A

±0,15 °C ±0,2 % of measured value

-

30 … +300 °C

AA =

1/3 DIN B

±0,1 °C ±0,17 % of measured value

0 … +150 °C

In order to achieve high exchange accuracy without the necessity of an additional

correction, we recommend using class A or AA temperature sensors.

5.2

Possible measuring errors

5.2.1

Immersion depth

Immerse to a depth of at least 20 mm and then stir. Otherwise, measuring errors can

occur due to the heat transmission of the sensor tube if the immersion depth

is too shallow.

Gas:

Immerse as far as possible into the gas to be measured so that the measur-

ing sensor is subjected to a heavy flow.

5.2.2

Surface effects and poor heat transfer

Special measuring sensors are required for this purpose. Surface characteristics, de-

sign of the measuring sensor, heat transfer and environmental temperature influence

the measurement result.

NOTE: Thermally conductive paste between the measuring sensor and surface can

also in-crease measurement accuracy in some cases.

5.2.3

Cooling / evaporation

When measuring the air temperature, the probe should be dry, otherwise the tempera-

ture measured will be too low.

5.2.4

Response time

An adequate wait time must be observed for the measuring process before reading the

measured value. The response time T

90

describes the time in which the displayed

measured value reached 90% of the end value.