05:7,*;(7730(5*,*64765,5;:(5+

79,<:,*/,*230:;

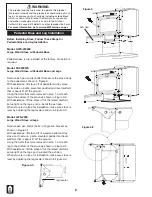

7SHJL[OLHWWSPHUJLPUHSVJH[PVUULHY[OLMPUHS

PUZ[HSSH[PVUHYLHHUKMVSSV^[OLWYVJLK\YLZILSV^!

6WLU[OLHWWSPHUJLHUKYLTV]LHSS[OLWHY[ZHUK

HY[PJSLZWHJRLKPUZPKL[OL*VTWVULU[7HJR

0UZWLJ[HSS[OLWHY[ZHUKNSHZZMVYZOPWWPUNKHTHNL

*VU[HJ[`V\YKLHSLYPMHU`PYYLN\SHYP[PLZHYLUV[PJLK

(SSZHML[`^HYUPUNZOH]LILLUYLHKHUKMVSSV^LK

;OPZ6^ULY»Z4HU\HSOHZILLUYLHK

-SVVYWYV[LJ[PVUYLX\PYLTLU[ZOH]LILLUTL[

=LU[PUNPZWYVWLYS`PUZ[HSSLK

;OLWYVWLYJSLHYHUJLZMYVT[OLHWWSPHUJLHUK

JOPTUL`[VJVTI\Z[PISLTH[LYPHSZOH]LILLUTL[

;OLTHZVUY`JOPTUL`PZPUZWLJ[LKI`HWYVMLZZPVUHS

HUKPZJSLHUVY[OLMHJ[VY`I\PS[TL[HSJOPTUL`PZ

PUZ[HSSLKHJJVYKPUN[VTHU\MHJ[\YLY»ZPUZ[Y\J[PVUZ

HUKJSLHYHUJLZ

;OLJOPTUL`TLL[Z[OLYLX\PYLKTPUPT\TOLPNO[

(SSSHILSZOH]LILLUYLTV]LKMYVT[OLNSHZZKVVY

(WV^LYV\[SL[PZH]HPSHISLULHYI`PMPUZ[HSSPUN

VW[PVUHSISV^LYHZZLTIS`

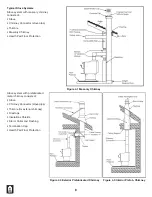

=,5;05.:@:;,4:

;OL]LU[PUNZ`Z[LTJVUZPZ[ZVMHJOPTUL`JVUULJ

[VYHSZVRUV^UHZZ[V]LWPWLHUKHJOPTUL`;OLZL

NL[L_[YLTLS`OV[K\YPUN\ZL;LTWLYH[\YLZPUZPKL[OL

JOPTUL`TH`L_JLLK-*PU[OLL]LU[VM

HJYLVZV[LMPYL;VWYV[LJ[HNHPUZ[[OLWVZZPIPSP[`VMH

OV\ZLMPYL[OLJOPTUL`JVUULJ[VYHUKJOPTUL`

T\Z[IL

WYVWLYS`PUZ[HSSLKHUKTHPU[HPULK

(UHWWYV]LK[OPT

ISLT\Z[IL\ZLK^OLUHJVUULJ[PVUPZTHKL[OYV\NOH

JVTI\Z[PISL^HSS[VHJOPTUL`(JOPTUL`Z\WWVY[WHJR

HNLT\Z[IL\ZLK^OLUHJVUULJ[PVUPZTHKL[OYV\NO

[OLJLPSPUN[VHWYLMHIYPJH[LKJOPTUL`;OLZLHJJLZZV

YPLZHYL

HIZVS\[LS`ULJLZZHY`

[VWYV]PKLZHMLJSLHYHUJLZ

[VJVTI\Z[PISL^HSSHUKJLPSPUNTH[LYPHS-VSSV^]LU[PUN

THU\MHJ[\YLY»ZJSLHYHUJLZ^OLUPUZ[HSSPUN]LU[PUNZ`Z

[LT

;663:(5+:<7730,:5,,+,+

)LMVYLILNPUUPUN[OLPUZ[HSSH[PVUILZ\YL[OH[[OLMVSSV^

PUN[VVSZHUKI\PSKPUNZ\WWSPLZHYLH]HPSHISL

9LJPWYVJH[PUNZH^

-YHTPUN4H[LYPHS

7SPLYZ

/P;LTW*H\SRPUN4H[LYPHS

/HTTLY

.SV]LZ

7OPSSPWZ/LHK:JYL^KYP]LY -YHTPUN:X\HYL

-SH[)SHKL:JYL^KYP]LY

,SLJ[YPJ+YPSS)P[Z¹

7S\TI3PUL

:HML[`.SHZZLZ

3L]LS

PUPUSLUN[OVY

;HWL4LHZ\YL

ZLSMKYPSSPUNZJYL^ZULLK

WLYWPWLZLJ[PVUJVUULJ[PVU

>(9505.

(ZWO`_PH[PVU9PZR

+V56;JVUULJ[[OPZ\UP[[VHJOPTUL`MS\LZLY]PJPUN

HUV[OLYHWWSPHUJL

+V56;JVUULJ[[VHU`HPYKPZ[YPI\[VUK\J[VYZ`Z[LT

4H`HSSV^MS\LNHZLZ[VLU[LY[OLOV\ZL

>(9505.

-PYL9PZR

0UZWLJ[ HWWSPHUJL HUK JVTWVULU[Z MVY KHTHNL

+HTHNLKWHY[ZTH`PTWHPYZHMLVWLYH[PVU

+V56;PUZ[HSSKHTHNLKJVTWVULU[Z

+V56;PUZ[HSSPUJVTWSL[LJVTWVULU[Z

+V56;PUZ[HSSZ\IZ[P[\[LJVTWVULU[Z

9LWVY[KHTHNLKWHY[Z[VKLHSLY

Summary of Contents for GWS-2200

Page 26: ...26 of 142 ...

Page 35: ...35 of 142 ...

Page 36: ...36 of 142 ...

Page 55: ...55 of 142 ...

Page 56: ...56 of 142 ...

Page 64: ...64 of 142 ...

Page 65: ...65 of 142 ...

Page 73: ...73 of 142 ...

Page 74: ...74 of 142 ...

Page 78: ...78 of 142 ...

Page 79: ...79 of 142 ...

Page 80: ...80 of 142 ...

Page 81: ...81 of 142 ...

Page 82: ...82 of 142 ...

Page 83: ...83 of 142 ...

Page 84: ...84 of 142 ...

Page 85: ...85 of 142 ...

Page 86: ...86 of 142 ...

Page 88: ...88 of 142 ...

Page 89: ...89 of 142 ...

Page 90: ...90 of 142 ...

Page 91: ...91 of 142 ...

Page 94: ...94 of 142 ...

Page 97: ...97 of 142 ...

Page 98: ...98 of 142 ...

Page 99: ...99 of 142 ...

Page 138: ...227 of 229 ...

Page 139: ...228 of 229 ...

Page 140: ...229 of 229 ...