9

Giacomini S.p.A.

Via per Alzo 39, 28017 San Maurizio d’Opaglio (NO) Italia

consulenza.prodotti@giacomini.com

+39 0322 923372 - giacomini.com

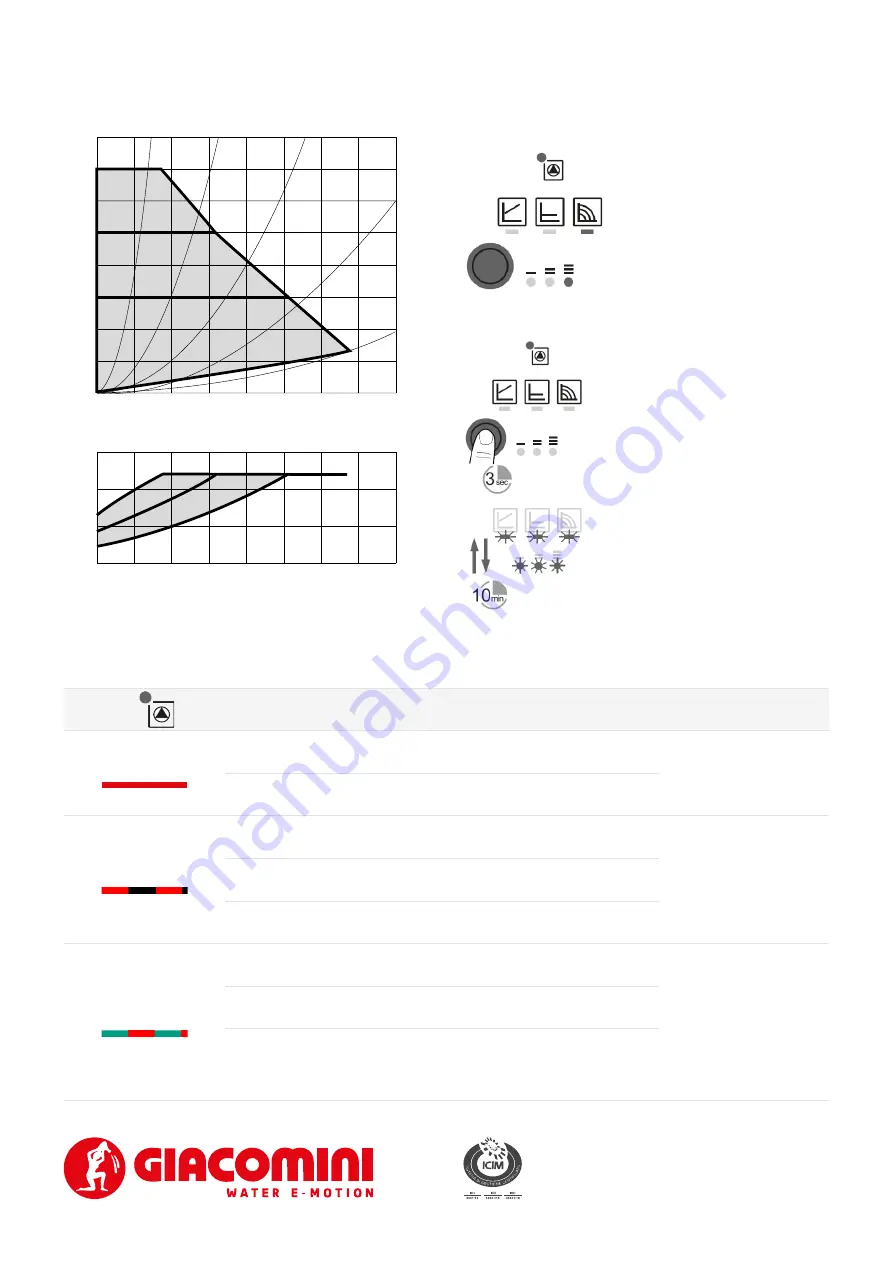

Constant differential pressure Δp-c (I, II, III) [RECOMMENDED]

0

0

1

2

0

20

40

60

3

4

5

6

7

8

∆

p-v (variabile)

0

10

20

30

40

50

60

70

80

0,5

1,0

1,5

2,0

3,0

4,0

3,5

2,5

0

0,5

1,0

1,5

2,0

3,0

4,0

3,5

2,5

Q [m

3

/h]

Q [m

3

/h]

P1 [W

]

H [m]

H [kP

a]

III

II

I

∆p-v

max.

max.

III

II

I

0

0

1

2

0

20

40

60

3

4

5

6

7

8

∆

p-c (costante)

0

10

20

30

40

50

60

70

80

0,5

1,0

1,5

2,0

3,0

4,0

3,5

2,5

0

0,5

1,0

1,5

2,0

3,0

4,0

3,5

2,5

Q [m

3

/h]

Q [m

3

/h]

P1 [W

]

H [m]

H [kP

a]

III

II

I

∆p-c

max.

max.

III

II

I

0

0

2

0

20

40

60

4

6

8

10

Velocità costante (I, II, III)

0

10

20

30

40

50

60

70

80

0,5

1,0

1,5

2,0

3,0

4,0

3,5

2,5

0

0,5

1,0

1,5

2,0

3,0

4,0

3,5

2,5

Q [m

3

/h]

Q [m

3

/h]

P1 [W

]

H [m]

H [kP

a]

III

II

I

III

II

I

Setting the control mode

The LED selection of control

modes and corresponding pump

curves takes place in clockwise

succession.

• Press the operating button briefly

(approx. 1 second).

LEDs display the set control

mode and pump curve.

Air venting

• Fill and vent the system correctly.

If the pump does not vent

automatically:

• Activate the pump venting function

via the operating button: press and

hold for 3 seconds, then release.

The pump venting function is

initiated and lasts 10 minutes.

The top and bottom LED rows

flash in turn at 1 second intervals.

To cancel, press and hold the

operating button for 3 seconds.

• After venting, the LED display shows

the previously set values of the pump.

Fault signals

• The fault signal LED indicates a fault.

• The pump switches off (depending on the fault) and attempts a cyclical restart.

LED

FAULTS

CAUSES

REMEDY

Lights up red

Blocking

Rotor blocked

Activate manual restart or

acontact customer service

Contacting/winding

Winding defective

Flashing red

Under/overvoltage

Power supply too low/high on mains side

Check mains voltage and

operating conditions, and request

customer service

Excessive module

temperature

Module interior too warm

Short-circuit

Motor current too high

Flashing red/green

Generator operation

Water is flowing through the pump hydraulics,

but there is no mains voltage at the pump

Check the mains voltage,

water quantity/pressure

and the ambient conditions

Dry run

Air in the pump

Overload

Sluggish motor, pump is operated outside of its

specifications (e.g. high module temperature).

The speed is lower than during normal operation

Circulator features