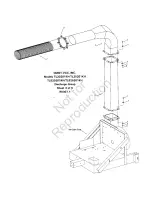

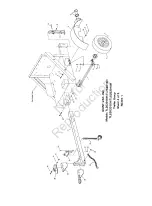

Giant-Vac Models TL20201KH, TLS20201KH, TL29202BVG & TLS29202BVG

Sheet 3 - DISCHARGE GROUP

REF.

PART

TL20201KH

TL29202BVG

NO.

NO.

DESCRIPTION

TLS20201KH TLS29202BVG

1

24640

Discharge Stack

1

1

2

24641

Discharge Elbow

1

1

3

31097

3/8-16 x 1-1/4" Hex Bolt

16

16

4

31034

3/8 Flat Washer

32

32

5

31008

3/8 Lock Washer

16

16

6

31009

3/8-16 Hex Nut

16

16

7

34021

Hose, Discharge 8" x 5' Metal

1

1

8

34048

Ring, Squeeze 8"

1

1

--

31086

1/2-13 x 1-3/4 Bolt

1

1

Not

for

Reproduction