12

7) When reassembling: The inlet valve seat (51C) is 1mm

smaller in diameter than the discharge valve seat (52C).

Inlet valve seats are marked “S” and always have to be

installed first. Discharge valve seats are marked “P” and

are always to be installed on top of inlet valve. Plugs (58)

are to be tensioned down evenly with screws (58C) and in

crosswise pattern at 155 ft.-lbs. (210 Nm).

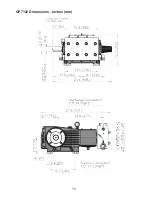

GP7122 REPAIR INSTRUCTIONS

11) By gripping hex flats,

separate plunger (36)

from crosshead (25) by

means of two open-end

wrenches (size 22mm

and 27mm).

8) Loosen nuts (49A)

with a 24mm socket

wrench.

9) With a rubber mallet tap

the back of the valve

casing (50) and pull the

valve casing off the stud

bolt (49).

10) Remove cover plate

(30) with a 10mm

socket wrench.

Valve Seat identification markings

TO CHECK SEALS

13) Pull seal sleeves (38)

and plungers (36) out

of their fittings in the

crankcase (1) using

ring groove as a guide.

Remove plunger from

seal sleeve.

12) Remove tension

spring (40) from seal

retainer (38).

CAUTION:

Don’t loosen the three plungers (36) before the valve casing has been

removed otherwise the plunger (36) could hit against the spacer pipe (51F)

when the pump is being turned.

Summary of Contents for GP7122

Page 8: ...8 Exploded View GP7122 ...