13

14) Remove circlip ring

(48) from seal sleeve

(38). Remove spacer

disc (47) and seal ring

(46) from seal sleeve.

Replace worn or dam-

aged parts.

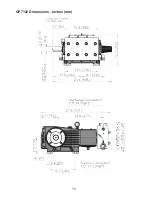

GP7122 REPAIR INSTRUCTIONS

16) Remove support disc (41) seal unit (42, 43, 44) and pressure ring (45) of seal sleeve

(38). Examine seals for signs of wear or cavitation, and if necessary, replace.

15) Remove leakage gasket (38B) from serrated pin (38A)

on the seal sleave (38). Check o-ring (38C) for damage

and replace if necessary.

IMPORTANT!

The 3.2 mm

(diameter bore of the leakage gasket (38B) must be

inserted directly on the serated pin (38A) of the seal

sleeve (38). The leakage gasket must fit snugly to the

seal so that the bevelled surface of the gasket faces

outwards.

48 47 46

38

38C

38B

36

33B

38A

45 44 43 42 43 42 41

NOTE:

Seal life can be increased

if the pretensioning allows

for a little leakage. This

assists lubrication and

keeps the seals cool. It is

therefore not necessary

to replace seals before

the leakage becomes too

heavy and causes output

and operating pressure to

drop.

17) Examine plunger surface (36)

for signs of wear or cavitation.

When exchanging worn plunger,

attention must be paid, so that the

center bore and front surface of the

crosshead (25) are free of dirt and

damage. When reinstalling, thread

plunger carefully through oiled seals

in seal sleeve (38). Coat thread of

new plunger lightly with bonding

agent (e.g., loctite).

Summary of Contents for GP7122

Page 8: ...8 Exploded View GP7122 ...