10

Pump System Malfunction

MALFUNCTION

CAUSE

REMEDY

The Pressure and/

Worn packing seals

Replace packing seals

or the Delivery

Broken valve spring

Replace spring

Drops

Belt slippage

Tighten or Replace belt

Worn or Damaged nozzle

Replace nozzle

Fouled discharge valve

Clean valve assembly

Fouled inlet strainer

Clean strainer

Worn or Damaged hose

Repair/Replace hose

Worn or Plugged relief valve on pump

Clean, Reset, and Replace worn parts

Cavitation

Check suction lines on inlet of

pump for restrictions

Unloader

Check for proper operation

Water in crankcase

High humidity

Reduce oil change interval

Worn seals

Replace seals

Noisy Operation

Worn bearings

Replace bearings, Refill crankcase

oil with recommended lubricant

Cavitation

Check inlet lines for restrictions

and/or proper sizing

Rough/Pulsating

Worn packing

Replace packing

Operation with

Inlet restriction

Check system for stoppage, air

Pressure Drop

leaks, correctly sized inlet

plumbing to pump

Accumulator pressure

Recharge/Replace accumulator

Unloader

Check for proper operation

Cavitation

Check inlet lines for restrictions

and/or proper size

Pressure Drop at Gun

Restricted discharge plumbing

Re-size discharge plumbing to

flow rate of pump

Excessive

Worn plungers

Replace plungers

Leakage

Worn packing/seals

Adjust or Replace packing seals

Excessive vacuum

Reduce suction vacuum

Cracked plungers

Replace plungers

Inlet pressure too high

Reduce inlet pressure

High Crankcase

Wrong Grade of oil

Giant oil is recommended

Temperature

Improper amount of oil in crankcase

Adjust oil level to proper amount

Check

Daily Weekly 50 Hrs. Every

500 Hrs.

Every

1500 Hrs.

Every

3000 Hrs.

Oil Level/Quality

X

Oil Leaks

X

Water Leaks

X

Belts, Pulley

X

Plumbing

X

Oil Change

(1 Gallon) p/n 01154

X

X

Plunger Seal Kit

(1 kit/pump) See page 5

X

Valve Repair Kit

(2 kits/pump) See page 5

X

Preventative Maintenance Check List & Recommended Spare Parts List

Recommended Spare Parts

Summary of Contents for LP200-SS

Page 4: ...4 Exploded View LP200 SS...

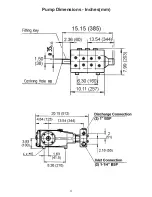

Page 11: ...11 Pump Dimensions Inches mm...