6

1) Loosen and remove

tension plugs (48) with a

36mm socket wrench.

TO CHECK VALVES

NOTE:

Always take time to lubricate all metal and non-metal parts with a light film of oil before reassembling. This step

will help ensure proper fit, at the same time protecting the pump non-metal parts (elastomers) from cutting and scoring.

44B 44A 45

2) Remove the support ring

(44B), O-ring (44A) and

tension spring (45).

3) Take out discharge valve

assemblies (46) by pull-

ing them upwards out of

the valve casing (43) with

a snap-ring tongs or any

other pull-off device. Then

remove inlet valves in the

same way.

4) Loosen valve seats (46A)

and valve spring (46C)

from spacer pipe (46D)

by lightly hitting the valve

plate (46B) with a plastic

stick. LP600/LP600-4000

pumps have an addi-

tional valve spring guide

(46E). Check sealing

surface and replace worn

parts. Reassemble with

new O-rings (44A) if pos

-

sible and oil them before

installing.

5) Tighten up tension plugs

(48) to 59 ft.-lbs. (80

Nm).

46A

46D

46B

46C

LP200-SS Repair Instructions

Summary of Contents for LP200-SS

Page 4: ...4 Exploded View LP200 SS...

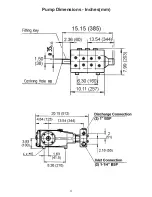

Page 11: ...11 Pump Dimensions Inches mm...