8. From the front of the manifold

(#43), remove the packing as

-

sembly (#41A, 41, 40, and 39).

Use a small slide hammer puller

if necessary, or insert a wooden

dowel through the back of the

manifold and tap the assembly

out from the back to the front.

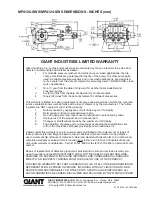

9. Turn the manifold (#43) over and remove the rear v-sleeve

snap ring (#36) and rear v-sleeve assembly (#35A-35D).

These parts should slide out with little resistance. If neces-

sary, a screwdriver may be used to pry outward. Replace

all rubber parts and inspect the metal parts for wear.

36 35D 35A 35B 35C

10.

Note: The following pro-

cedure is only necessary

if a stud bolt (#49) has

been damaged and must

be replaced.

To remove

the manifold studs (#49),

place a stud nut (#50),

lock washer (#50A), and

second nut on each stud.

Tighten the nuts against

each other. Hold the front

nut with one wrench, and

remove the stud bolt by

turning the rear nut coun-

terclockwise with another

wrench. To reassemble,

turn the front stud bolt nut

clockwise.

11. Inspect ceramic plunger pipe (29B). Clean any dirt or

grime. If the surface of the pipe is rough, scored or pitted,

replace plunger pipe. To remove the ceramic plunger

pipe, turn the plunger bolt (#29C) counterclockwise with

a 13mm socket. Use a steady torque to prevent ceramic

plunger pipe damage. Loosen and remove the plunger

bolt assembly (#29C and #29D) and replace the seal

washer (#29D).

12. Inspect the crankcase oil

seals (#31) for evidence of

leaking. If there is oil on

the crankcase (#1) at the

sight of the oil seals, they

must be replaced. The oil

seals are replaced after

removing the crosshead/

plunger assembly (#25) as

described on page 9.

31

REPAIR INSTRUCTION - MP4120-SWS/MP4124-SWS

8

29C 29D 29B

13. Clean the bolt threads

(#29C), apply locktite,

and remount.

14. Torque the ceramic plunger

bolt assembly to 300 inch-

pounds (34 Nm). If origi

-

nally removed, reinstall the

stud bolts (#49).