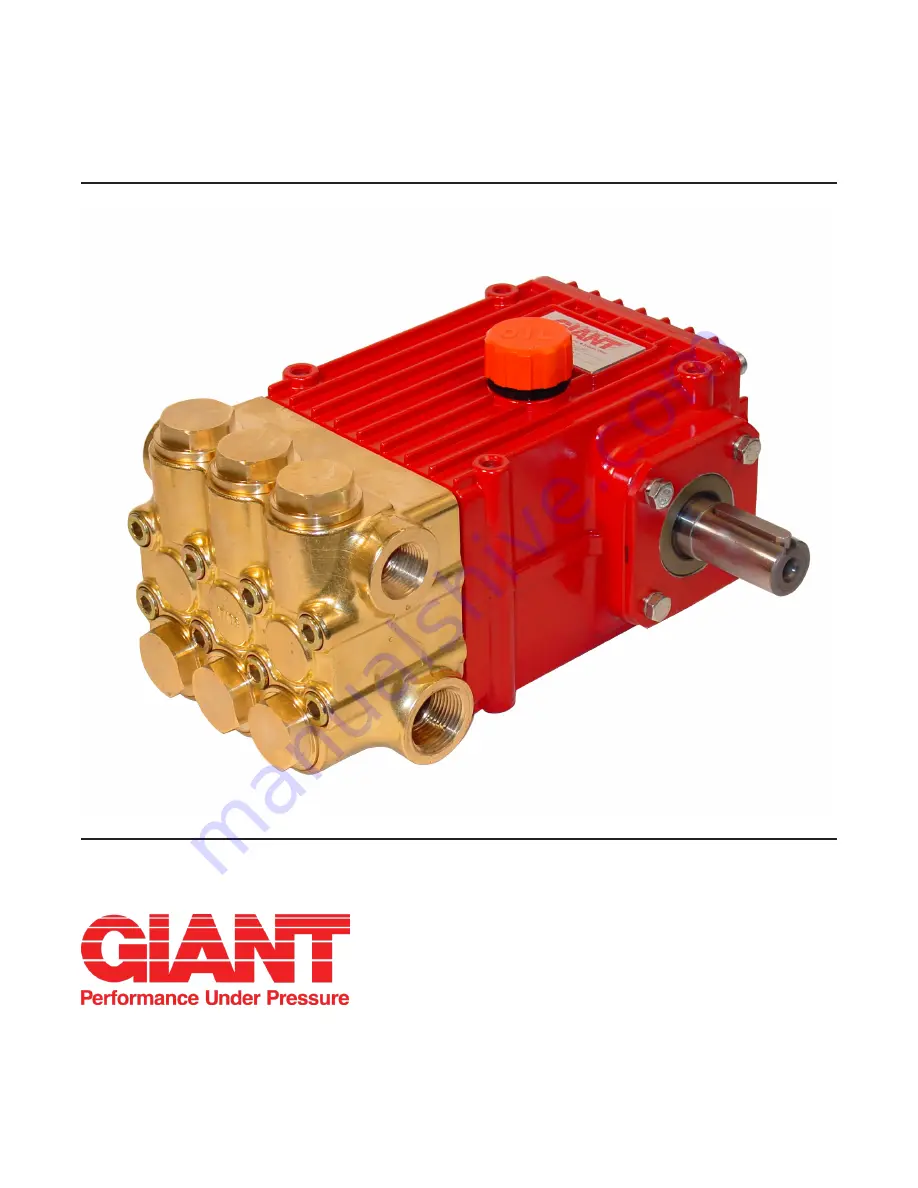

P435

P455B Pumps

Triplex Ceramic

Plunger Pump

Operating Instructions/

Repair and Service Manual

Contents:

Installation Instructions:

page 2

Pump Specifications:

pages 3 & 6

Exploded View:

page 4

Parts List/Kits:

page 5

Repair InstructionsTorque Specs.:

pages 7-9

Trouble Shooting Chart:

page 10

Recommended Spare Parts List:

page 10

Dimensions:

page 11

Warranty Information

back page

Updated 01/18

Summary of Contents for P435

Page 4: ...4 EXPLODED VIEW P435 P455B...

Page 11: ...11 P435 P455B Dimensions in mm...