20

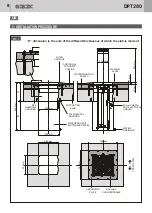

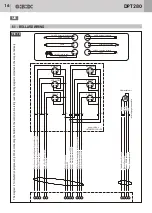

7.4 - MASTER CIRCUIT BOARD CONNECTIONS

Terminal Contact

1-2-3

31-32-33

46-47-48

51-52

34-39

40-41-42

43-44-45

49-50

4

5

53

54

55-59

6-7-8

9-10

15

16

28-30

29-30

13

17

11-12

14

24-25

26-27

60-61

62-63

64-65

65-66

67-68-69

20-21

22-23

N.C.

N.O.

N.O.

N.O.

N.O.

N.C.

N.O.

N.O.

N.C.

LED

Connected device

Through terminals 31-32-33. Protected by F5 fuse

Through terminals 1-2-3. Protected by F5 fuse

Outlet for traffic light signal (neutral exchange)

Inlet for 230V power supply

Inlet/outlet for transformer connection

Outlet 230V

(40= red - 41= green - 42= common)

connection to traffic light

Outlet 230V connection to traffic light (40= red - 41= green - 42= common)

Inlet for breaking glass button - emergency automatic lowering

(only for bollards equipped with automatic lowering - NO 230V)

Grounding for hydraulic pump motor

None

None

Inlet for grounding

Inlet/outlet connection to yearly/weekly progremmer

Outlet 230V power supply for hydraulic pump (common terminal 8)

L7

L3

L4

L1

L2

L13

L13

LIN

L5

L12

L11

L14

Outlet 24V power supply for solenoid valve

Outlet 24V power supply for acoustic buzzer

Outlet 24V power supply for flashing light

Outlet 24V power supply for radio receiver

Outlet 12V power supply for radio receiver

Common: Lower limit switch - Acoustic buzzer - Flashing light

Common: Lower limit switch - Acoustic buzzer - Flashing light

Inlet for pressure switch or upper limit switch

Inlet for lower limit switch

Start command inlet (lowering control or step/step)

Inlet command from radio receiver (lowering control or step/step)

Inlet for future functions or customizations

Outlet for future functions or customizations

Inlet for lowering command (common terminal 65)

Inlet for rising command (common terminal 65)

CAN-BUS connection slave circuits (67= CANH - 68= CANL - 69= 0V)

Inlet for safety devices (example: inductive loops detector)

Outlet 24V power supply for safety devices (example: inductive loops detector)

DPT280

UK