29

Attention

!

The following instructions are exclusively intended for competent / qualified persons with

suitable training, specialist knowledge and practical experience sufficient to correctly and safely fit,

test, and carry out maintenance on a bollard system .

In order to ensure the correct function and a constant safety level, perform the following inspections and test on the

bollard system, safety devices and connected accessories every six months.

9 - MAINTENANCE

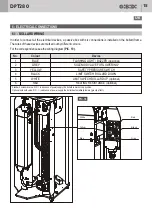

Inspection and cleaning of the

foundation box, including

removal of dirt. (A001)

Cleaning the drains for water

discharge on the floor of the

foundation box. (A002)

General cleaning of the bollard

and possible repair of cylinder

paint damages. (A003)

Bollard lubrication. (A004)

Check of the lower support

bases. (A005)

Check the proper position

of the magnetic contact and

magnet . (A006)

Operation

Procedure

Check the condition of the inside of the foundation box. If necessary, clean the

foundation box using an appropriate vacuum for liquids and solids. All dirt that

has collected inside must be removed (sand, soil, gravel and similar).

There are openings for draining rainwater in the 4 corners on the floor of the

foundation box. The openings can partially or fully block or become calcified over

time, meaning that drainage of rainwater is limited or not possible at all. To

remove any possible calcification, take an appropriately long drill (Ø 15 mm) and

drill the openings clear. Lower the drill approx. 10 cm into the gravel below.

Rise the cylinder if the bollard is dry. Lubricate the central sliding guide (external

part of the piston that slides on the cylinder) and the piston rod if possible.

Use TEFLON OIL, if possible, due to its long-lasting lubrication effect.

When the bollard is lowered, the cylinder is positioned on three contact surfaces

at the bottom. These bottom contact surfaces are made of aluminium with a top

part made of vulcanised solid rubber. The solid rubber can wear over time. Check

the solid rubber top parts for wear or damages and replace them if necessary.

Lower the bollard to down position then check that the magnetic contact, placed

in the lower part of the frame, and the magnet, placed on the moving cylinder, are

properly alligned.

DPT280

UK

Check the cleanliness of the bollard. Clean the entire bollard, if necessary, with a

suitable high-pressure cleaner (with warm water if possible). Clean the bollard in

the lowered position first. Extend the bollard and clean the surface of the cylinder.

If possible, also clean the sliding area between the cylinder (moving part) and the

frame (fixed part).

Check the cylinder with regard to its visual impression and repair any paint

damages on the cylinder if necessary.