36

11 - TROUBLESHOOTING

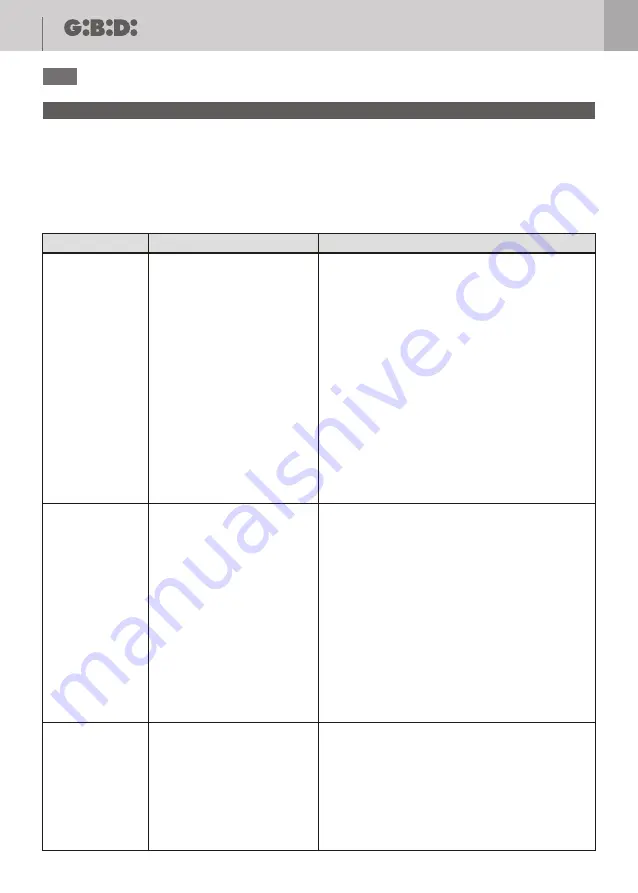

The bollard rises

of about 10 cm,

stops and then

returns in low

position (without

any lowering

control). (C001)

The bollard rises

but not

completely.

(C002)

Once the bollard

is in down

position, the

cylinder is about 7

mm lower than the

frame cover.

(C003)

The safety pressure switch which

detects the presence of about 40

Kg weight on the bollard head is

constantly in ON position and for

this reason it must be adjusted or

replaced.

• There is too little oil in the

hydraulic pump tank.

• Bollard's connecting cables are

not well placed in the foundation

box. If the upper limit switch gets

stuck in the cable, the function of

the bollard may be impared.

The vulcanized hard rubber of the

lower base supports is worn.

PROBLEM

POSSIBLE CAUSE

SOLUTION

When the bollard is in low position check the leds L1 on

the master and/or the slave unit in the control unit:

switched off = the pressure switch is ok – turned on = the

pressure switch is in alarm (it is on) – if the led is always

turned On or turns On when the bollard starts rising, the

problem is caused by the dafety pressure switch which

must be adjusted or replaced.

For the pressure switch adjustment please consult

chapter 10: SPECIFIC OPERATIONS.

Note: generally only the pressure switches of old supply

are adjustable and recognizable from a waterproof

protection made by black soft rubber; the current

pressure switches are pre-adjusted and hermetic to

increase the IP grade of protection.

• Check whether oil is leaking from the hydraulic

assembly, hydraulic lines or connections. Check

whether all hydraulic connections are properly

tightened using a corresponding open ended spanner.

Refill oil into the hydraulic assembly once the oil leak

has been remedied. Read chapter 10: SPECIFIC

OPERATIONS.

• Pull the bollard out from the foundation box and check

if the bollard can fully rise. If the test is positive, put the

bollard back into the foundation box and make sure that

the connecting cables are positioned correctly.

Replace the lower support bases.

DPT280

UK

This guide shows the most common problems that can occur while using a GI.BI.DI.

Client's technicians can solve some problems indipendently (especially if they are equipped with spare parts), while

for other troubles it may be necessary to be supported by GI.BI.DI. S.r.l assistance department.

In this case they have to contact GI.BI.DI. S.r.l., communicate the reference number of the system (or the reference

number of the order confirmation).