22/32

03.06.20, Subject to alterations

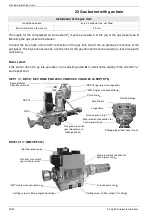

Calculation principles for gas burner adjustment

23 Calculation principles for

gas burner adjustment

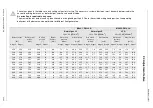

The values given in the tables are setting values for start-up.

The necessary system adjustment must be newly determined in each case.

General:

The calorific value (H

i,n

) of fuel gases is generally specified for the normal state (0°C, 1013 mbar).

Natural gas type E

H

i,n

= 10.4 kWh/m

3

Natural gas type LL

H

i,n

= 9.3 kWh/m

3

Gas counters measure the volume of gas in the operational state.

Gas flow determination:

To allow the heat generator load to be adjusted correctly, the gas flow rate must be determined in advance.

Example:

Height above sea level

230 m

Atmospheric pressure B (acc. to Tab.) 989 mbar

Gas pressure P

G

at gas meter

20 mbar

Gas temperature

ϑ

G

16°C

Boiler output Q

n

220 kW

Efficiency

η

K

(assumed)

92%

Calorific value H

i,n

10.4 kWh/m

3

Gas flow in standard state (V

n

)

Gas flow in operating state (V

B

)

Conversion factor (f)

Annual average air pressure

Legend:

Q

n

=

boiler output [kW]

η

K

=

efficiency [%]

H

i,n

=

lower standard calorific value [kWh/m

3

]

f =

conversion factor

B =

atmospheric pressure [mbar]

p

G

=

gas pressure at gas meter [mbar]

ϑ

G

=

gas temperature at gas meter [°C]

Average geodetic altitude of the

supply region above sea level [m]

from

1

51

101

151

201

251

301

351

401

451

501

551

601

651

701

to

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

Annual average of air pressure

(mbar) 1016 1013 1007 1001 995

989

983

977

971

965

959

953

947

942

936

930

V

n

Q

n

η

k

H

×

i n

,

--------------------

220

kW

0 92

10

×

4

kWh

m

3

-----------

,

,

----------------------------------------

=

23

m

3

h

------

=

=

V

B

V

n

f

------

23

m

3

h

------

0 94

,

-------------

=

24

m

3

h

------

=

=

f

B P

G

+

1013

--------------

273

273

ϑ

G

+

--------------------

×

=