Su

b

je

c

t t

o

a

lte

ra

tio

n

s,

0

3

.0

6

.2

0

2

3

/3

2

Ad

ju

s

tm

e

n

t t

a

b

le

s

2

4

A

d

ju

s

tm

e

n

t t

a

b

le

s

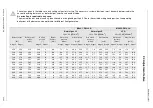

The values given in the tables are only setting values for start-up. The necessary system adjustment must be newly determined in the

case of deviating data such as boiler output, calorific value and altitude.

A correction is required in any case.

The maximal burner output can only be achieved in mixing head position 0. Due to the variable mixing head position, the operating

behaviour of the burner can be optimised for different heat generators.

MG20/1-ZM-L-LN

MG20/2-ZM-L-LN

Natural gas LL

Hi,n = 9.3

[

kWh/m

3

]

Natural gas E

H

i,n

= 10.4 [kWh/m

3

]

LPG

H

i,n

= 25.89 [kWh/m

3

]

Burner output

[kW]

Boiler output

η

= 92%

[kW]

Air flap

position

[ ° ]

Burner

heat pos.

[mm]

Gas nozzle

pressure

[mbar]

Gas flow rate

[m

3

/h]

Gas nozzle

pressure

[mbar]

Gas flow rate

[m

3

/h]

Gas nozzle

pressure

[mbar]

Gas flow rate

[m

3

/h]

Stage 2

Stage 1

Stage2

Stage1

Stage2 Stage1 Stage2 Stage1 Stage2 Stage1 Stage2 Stage1 Stage2 Stage1 Stage2 Stage1

450

224

419

26.0

9

22

7.3

2.1

49.9

24.8

5.7

1.6

44.6

22.2

7.4

2.0

17.4

8.7

520

260

484

33.0

12

22

9.6

2.7

57.6

28.8

7.5

2.1

51.5

25.8

9.5

2.7

20.1

10.0

600

300

558

40.0

14

22

12.0

3.5

66.5

33.3

9.4

2.7

59.5

29.7

12.1

3.6

23.2

11.6

740

370

688

90.0

19

22

14.7

5.0

82.0

41.0

11.5

3.9

73.4

36.7

17.4

5.2

28.6

14.3

560

280

521

30.5

13

10

7.9

2.7

62.1

31.0

6.2

2.1

55.5

27.8

9.4

2.9

21.6

10.8

640

320

595

36.0

17

10

10.3

3.5

70.9

35.5

8.1

2.7

63.4

31.7

11.8

3.6

24.7

12.4

760

380

707

51.0

21

10

14.5

4.8

84.2

42.1

11.3

3.8

75.3

37.7

16.0

4.8

29.4

14.7

813

410

756

90.0

22.5

10

16.2

5.2

90.1

45.4

12.7

4.1

80.6

40.6

18.0

5.5

31.4

15.8

600

300

558

30.0

10

0

9.1

2.8

66.5

33.3

7.1

2.2

59.5

29.7

9.0

2.9

23.2

11.6

680

340

632

34.0

13

0

11.2

3.5

75.4

37.7

8.8

2.7

67.4

33.7

11.3

3.5

26.3

13.1

780

390

725

44.0

17

0

14.3

4.3

86.5

43.2

11.2

3.4

77.3

38.7

14.5

4.3

30.1

15.1

860

430

800

90.0

20

0

17.4

5.0

95.3

47.7

13.6

3.9

85.2

42.6

17.4

5.1

33.2

16.6