MarkLED 4

Page 9 / 38

Created

03.10.2017

chal

Modified

28.11.2017

chal

Object-ID

850593

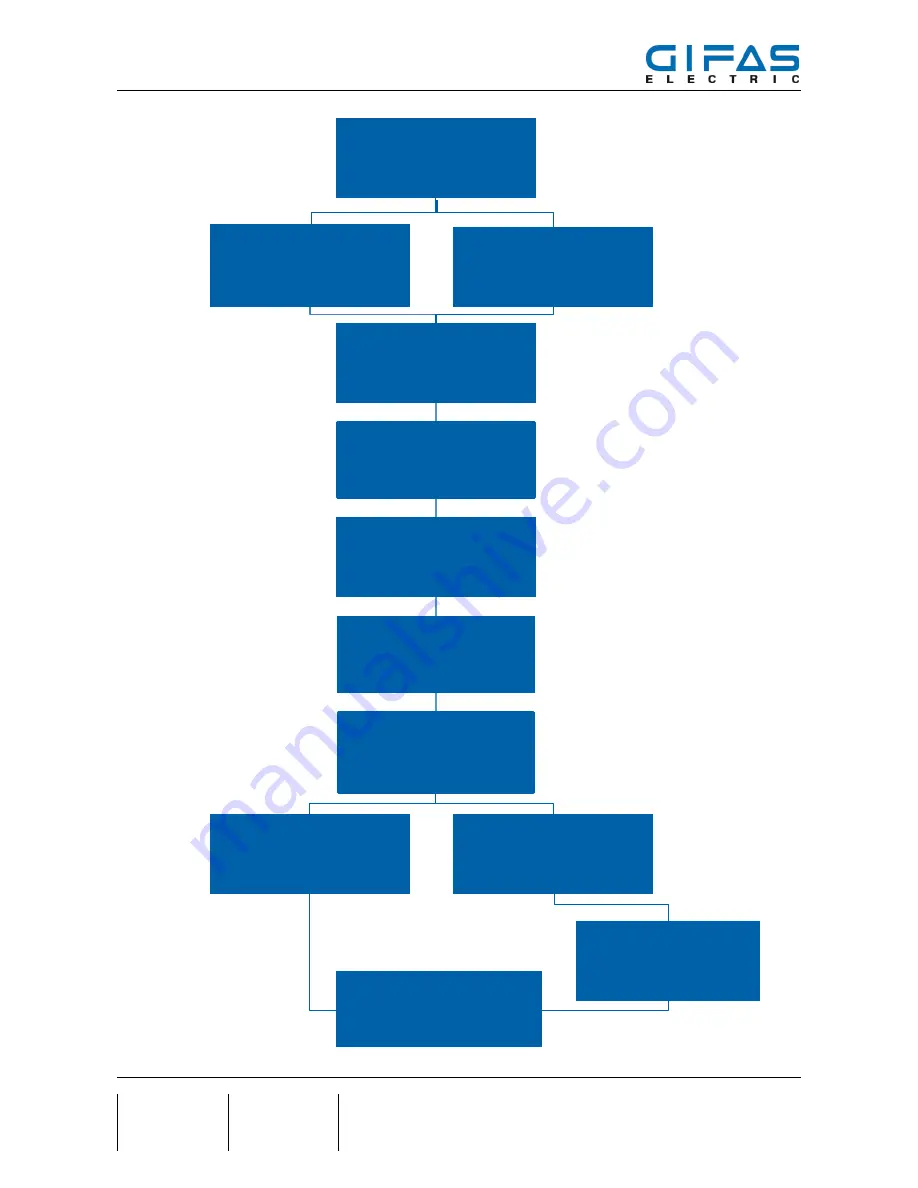

1.

Measure and mark

2a.

Milling a groove in the

shoulder

2b.

Remove bitumen from

groove / remove old system

3.

Rework of groove for cur-

rent collector

4.

Inserting the connecting

cables

5.

Mount current collector onto

system cable

6.

Install current collector in

groove

7.

Put on the MarkLED

8a.

Seal groove

8b.

Insert system profile

10.

Installation of the control unit

including parameterisation

9.

Seal MarkLED

4 Process