RoadLED 50m

Page 15 / 20

Created

23.04.2021

rasa

Modified

06.10.2021

rasa

Object-ID

2214657

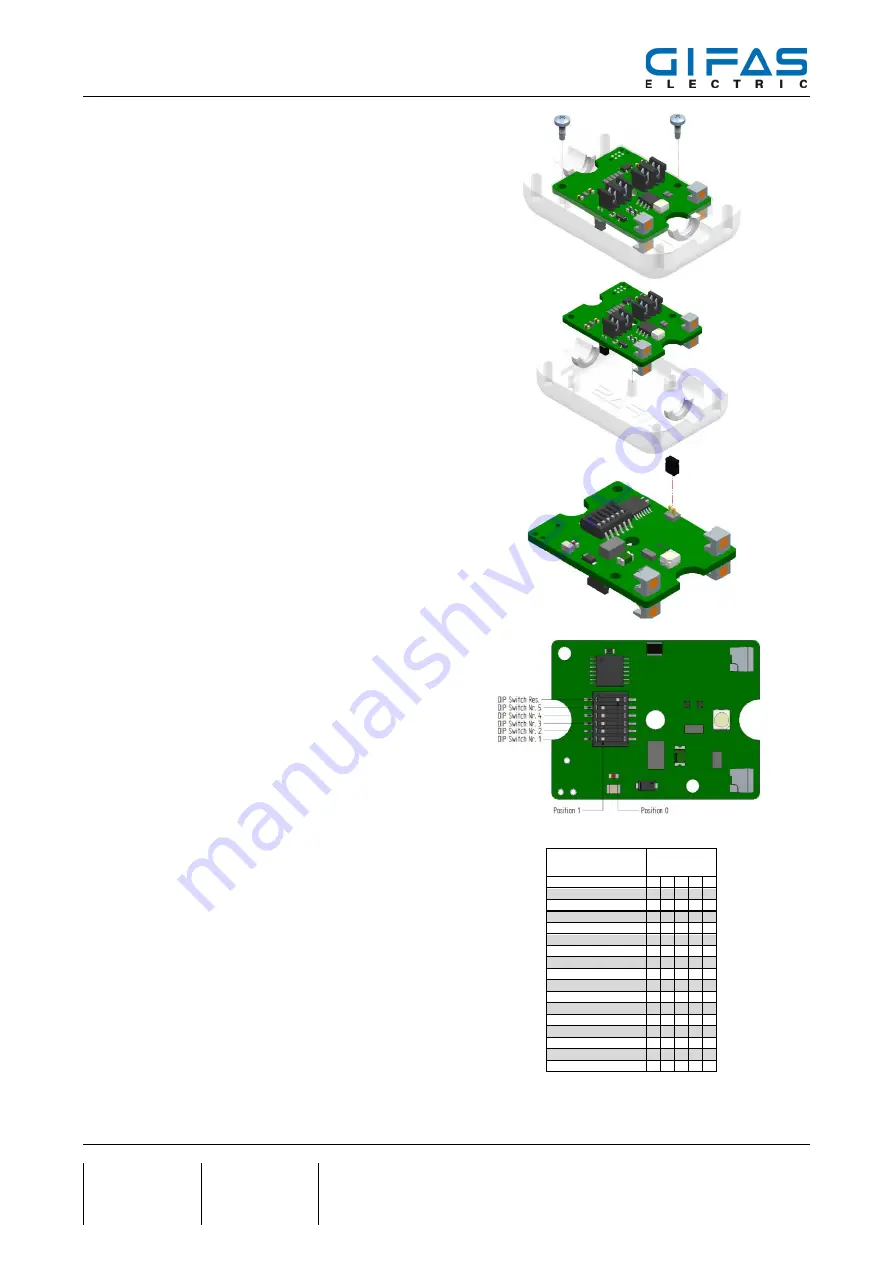

3. Dismantle the electronics

Loosen the screws with a Torx T6 screwdriver

and remove the electronics.

4. Remove the electronics

Remove the electronics. Consider the ESD pro-

tection measures.

5. Set the jumper

If the light module at the end of the cable is

replaced, the jumper must be inserted as

shown above. The jumper serves as a

terminating resistor and prevents reflections in

the cable.

6. Transfer the DIP switch settings

Transfer the DIP switch from the old module to

the new module

If a switch is moved to the right, the respective

address is interpreted as 0. If a switch is moved

to the left, the respective address is interpreted

as 1.

If a configuration is no longer recognisable, the

setting can be taken from the following table

The light module with address 1 is located at

the beginning of the cable reel. The light mo-

dule with address 16 is located at the end of the

cable.

Example: The address of the light module

should be set to address 16. According to the

table in section 6. DIP switch no. 1, 2, 3 and 4

must be in position 1 and DIP switch no. 5 in

position 0.

Adresse RoadLED

Position DIP-

Switch

DIP Switch Nr.

5 4 3 2 1

Adresse 1

0 0 0 0 0

Adresse 2

0 0 0 0 1

Adresse 3

0 0 0 1 0

Adresse 4

0 0 0 1 1

Adresse 5

0 0 1 0 0

Adresse 6

0 0 1 0 1

Adresse 7

0 0 1 1 0

Adresse 8

0 0 1 1 1

Adresse 9

0 1 0 0 0

Adresse 10

0 1 0 0 1

Adresse 11

0 1 0 1 0

Adresse 12

0 1 0 1 1

Adresse 13

0 1 1 0 0

Adresse 14

0 1 1 0 1

Adresse 15

0 1 1 1 0

Adresse 16

0 1 1 1 1