3

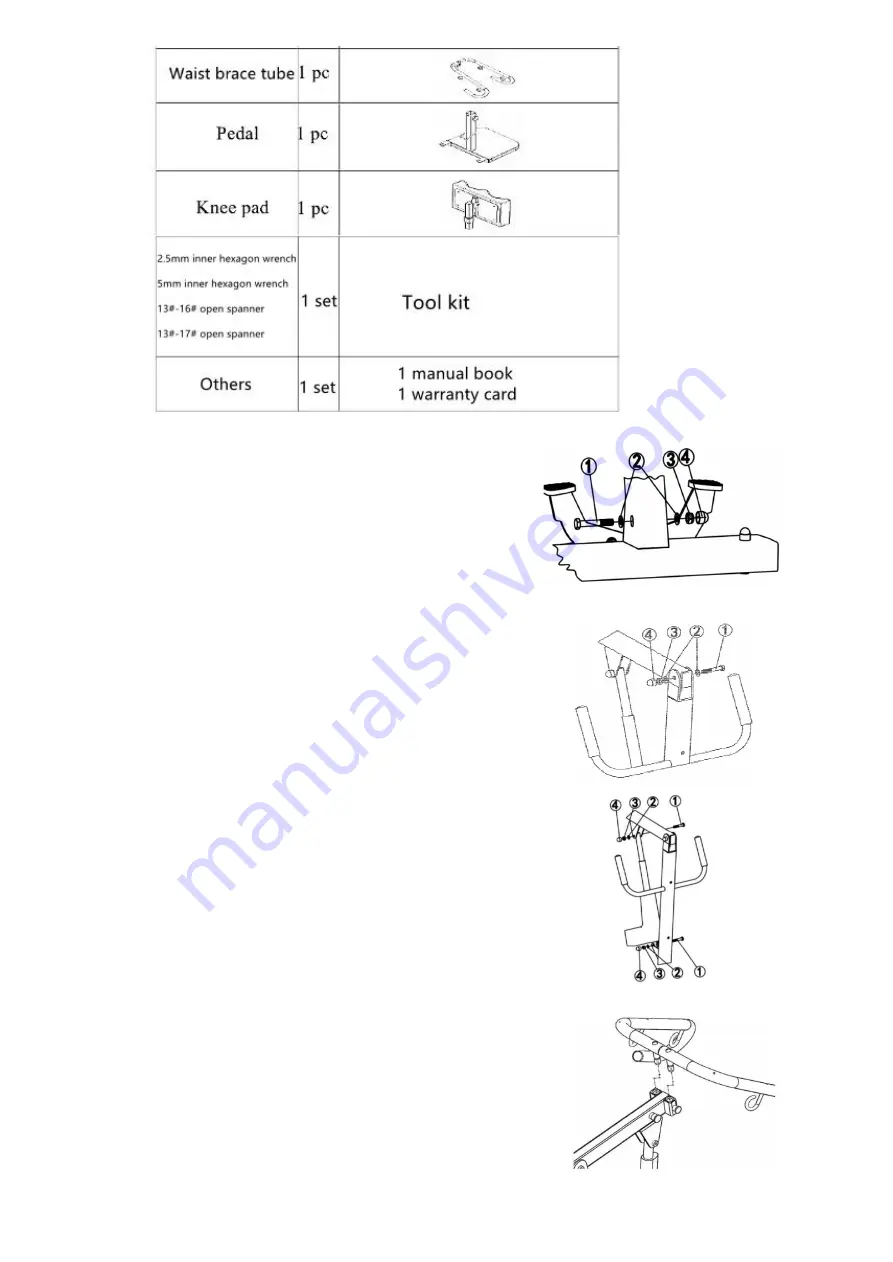

1. Installation steps

Step 1: Raise the body frame,Screw the M10x75

outer hexagon bolt as drawings.

①

Bolt M10x75

②

Gasket

③

Nylon lock nut M10

④

Nut

Step 2: Connect the rear lift tube with the

body frame shown in the drawing, tighten by

M10x50 Hexagon bolt and nuts .

①

Hexagon socket shoulder screw M10X50

②

Gasket

③

Nylon lock nut M8

④

Nut

Step 3: Install the motor, tighten by

M10x40 Hexagon bolt and nuts

①

Hexagon socket shoulder screw M10x40

②

Gasket

③

Nylon lock nut M8

④

Nut

Step 4: Install waist brace tube, Align the two pins

on the waist brace tube to the two holes on the rear

lifting tube press down, hear a “click”