Operation

MetPak Base Station User Manual

Last Change

©

Gill Instruments Ltd

22 April, 2013

Page 39

3.4.2

MetSet Editing Screen

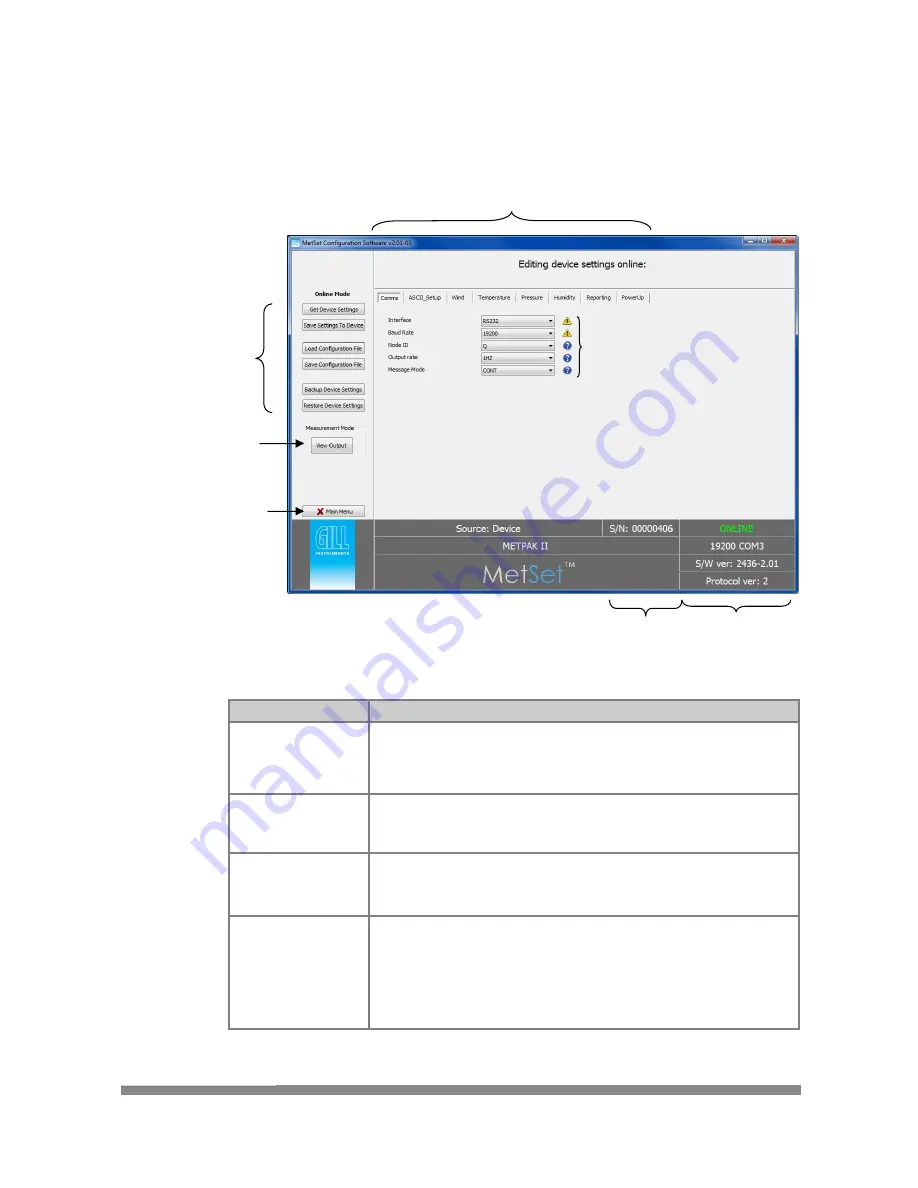

When connected correctly a MetSet editing screen is available to read

configuration settings, change configuration settings, save MetPak Base Station

configuration settings to a PC file location, upload MetPak Base Station

configuration settings from a PC file and view the MetPak Base Station raw data

string output.

MetSet Connection Status Information.

Reading

Function

ONLINE

ONLINE in green indicates the MetPak Base Station has been

successfully connected to MetSet.

OFFLINE in Grey indicates that MetSet is being used without a

MetPak Base Station in communication with MetSet.

19200 COM 3

19200 is a report on the MetPak Base Station Baud rate setting.

COM 3 is a report on the MetPak Base Station COM Port

connection number.

S/W ver 2436-2.01

2436 is the MetPak Base Station Firmware number

2.01 is the firmware revision.

Protocol Ver:2 (Gill Internal Reference).

Source:Device

MetSet reads ‘Device’ when the source of the data that MetSet

has retrieved has come from the MetPak Base Station.

MetSet reads ‘File’ when the source of data has come from a

saved file.

MetSet reports on the connected MetPak device (e.g. METPAK)

and reads the unit Serial Number (S/N: 00000406)

Connection Status

MetPak Editing Pages

MetPak Device

Setting Options

View MetPak

Pro Raw Data

Output String

Serial Number

Move mouse over

exclamation or question

marks to read setting

comment

Return to

opening MetSet

Screen