Electrical System

393

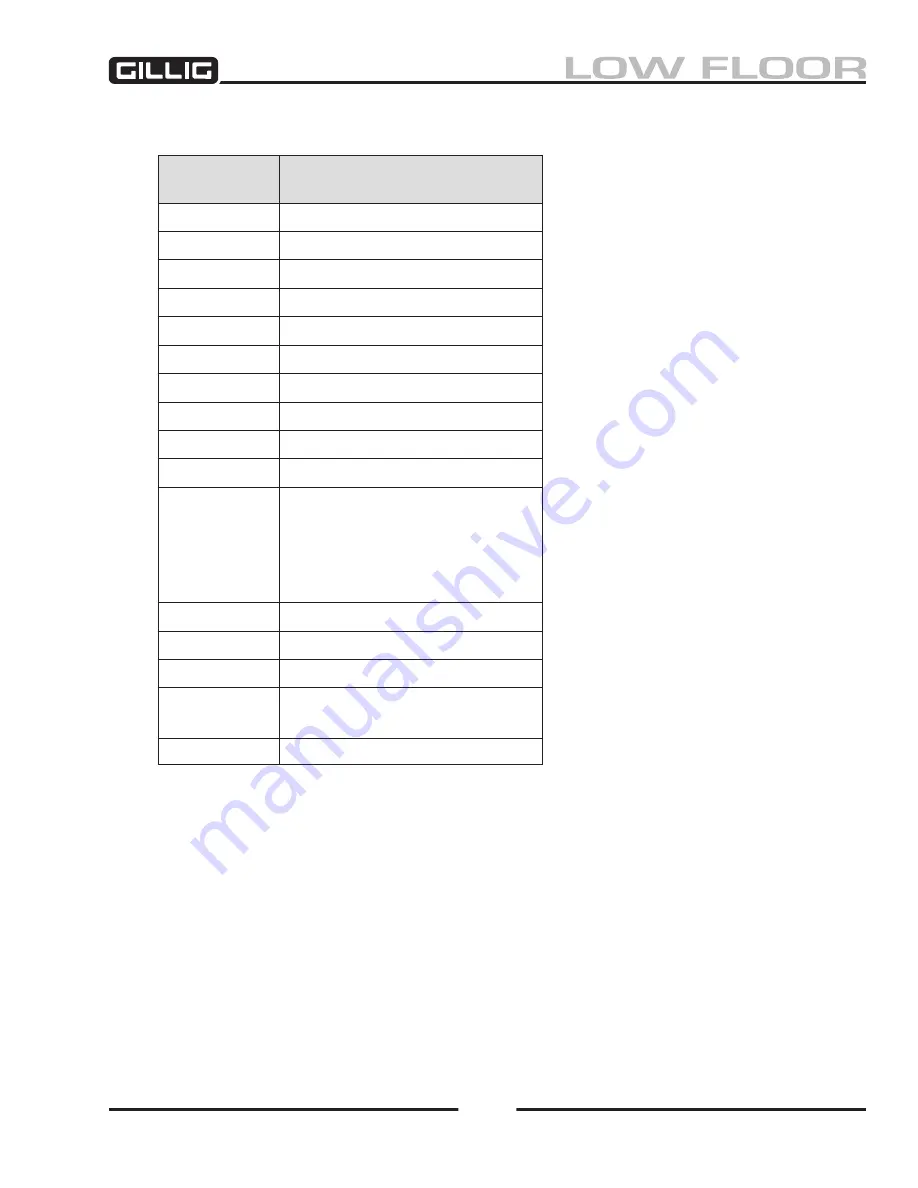

DINEx Flash Codes (Continued)

Off

Dinex communication OK

1 Flash

Module A1 #64 Comm Fault

2 Flashes

Module A2 #65 Comm Fault

3 Flashes

Module A2 #66 Comm Fault

4 Flashes

Module B1 #67 Comm Fault

5 Flashes

Module B1 #68 Comm Fault

6 Flashes

Module B2 #69 Comm Fault

7 Flashes

Module B3 #70 Comm Fault

8 Flashes

Module C1 #71 Comm Fault

9 Flashes

Module D1 #72 Comm Fault

10 Flashes

Incorrect DINEX program or

incorrect accessory (Palm PC)

Note: Module D2 #73 is the

master unit and does not check

itself.

11 Flashes

Module D3 #74 Comm Fault

12 Flashes

Module B4 #75 Comm Fault

13 Flashes

Module D4 #76 Comm Fault

14 Or More

Incorrect DINEX program or

incorrect Accessory (Palm PC)

15 Flashes

Module B5 #78 Comm Fault

COMM FAULT

Lamp is:

Meaning

Summary of Contents for LOW FLOOR

Page 18: ...Specifications 18...

Page 58: ...Preventive Maintenance 58...

Page 110: ...Engine 110...

Page 138: ...Transmission Driveline Rear Axle 138...

Page 182: ...Suspension 182...

Page 260: ...Air System 260...

Page 420: ...Electrical System 420 Deutsch DT Series Connectors...

Page 421: ...Electrical System 421...

Page 422: ...Electrical System 422 Deutsch HD 10 Series Connectors...

Page 423: ...Electrical System 423...

Page 424: ...Electrical System 424 Deutsch HD 30 Series Connectors...

Page 425: ...Electrical System 425...

Page 442: ...Heating Air Conditioning 442...

Page 492: ...Body and Interior 492 Figure 11 33 USSC Seat Assembly...

Page 493: ...Body and Interior 493 Figure 11 34 USSC Seat Suspension Assembly...

Page 495: ...Body and Interior 495 Figure 11 37 Seat Air Connections...