Preventive Maintenance

43

5 6 7

5

8

3

2

4

3

2

4

3

2

3

2

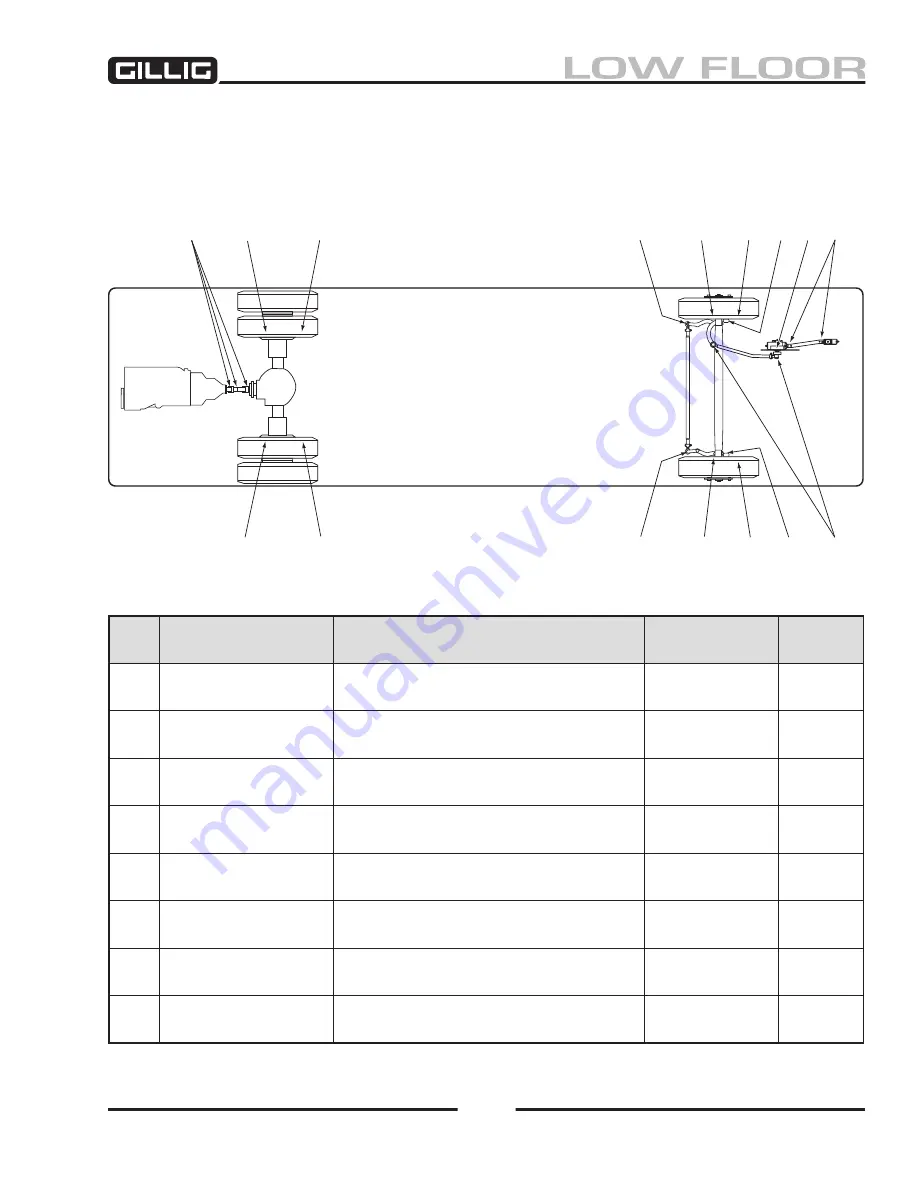

Figure 2-1, Lube Points

LUBRICATION POINTS

Refer to Figure 2-1 and its accompanying table for grease points on your coach. Also refer to Figure 2-2

for steering system preventive maintenance intervals. Keep in mind that there are many other compo

-

nents on the coach which require regular maintenance.

Item

Component

Note:

Lubricant

Interval,

Miles

1

driveshaft

Three fittings: two U-joints, one slip

shaft

Nlgi #2 ep

grease

8,000

2

brake camshaft

bushings

Four fittings, one at each wheel end

Nlgi #1 or #2

mp grease

50,000

3

slack Adjusters

Four fittings, one at each wheel end

Nlgi #1 or #2

mp grease

6,000

4

tie rod ends

Two fittings, one at each rod end

Nlgi #1 or #2

mp grease

50,000

5

front Axle King pins

Four fittings, two at each axle end

Nlgi #1 or #2

mp grease

50,000

6

output shaft seal

One fitting atop steering gear, use

90° grease-gun fitting

Nlgi #1 or #2

mp grease

24,000

7

intermediate shaft

Two fittings, one at each U-joint

Nlgi #2 ep

grease

24,000

8

drag link

Two fittings, one at each rod end

Nlgi #1 or #2

mp grease

10,000

Summary of Contents for LOW FLOOR

Page 18: ...Specifications 18...

Page 58: ...Preventive Maintenance 58...

Page 110: ...Engine 110...

Page 138: ...Transmission Driveline Rear Axle 138...

Page 182: ...Suspension 182...

Page 260: ...Air System 260...

Page 420: ...Electrical System 420 Deutsch DT Series Connectors...

Page 421: ...Electrical System 421...

Page 422: ...Electrical System 422 Deutsch HD 10 Series Connectors...

Page 423: ...Electrical System 423...

Page 424: ...Electrical System 424 Deutsch HD 30 Series Connectors...

Page 425: ...Electrical System 425...

Page 442: ...Heating Air Conditioning 442...

Page 492: ...Body and Interior 492 Figure 11 33 USSC Seat Assembly...

Page 493: ...Body and Interior 493 Figure 11 34 USSC Seat Suspension Assembly...

Page 495: ...Body and Interior 495 Figure 11 37 Seat Air Connections...