Gilson Company, Inc.

Gilson Binder Ignition System: HM-378

Page 13

k. To hold elements in grooves, reinstall staples at

marked locations by pressing them in using a

pair of long nose pliers.

If the element is slightly too long when you reach

the second firebrick hole, insert element end into

the firebrick hole and let the curved groove take up

the extra length. You can compress the element

with long nose pliers if necessary. If the element

is several inches too long, it was not pushed all

the way to the back of each corner and should be

re-threaded. If the element is too short to reach

the second firebrick hole, unthread some of it.

Gently stretch it in your hands. Avoid stretching

only a short portion of the element. It is better to

distribute the stretch over a longer section.

Press the element down into the lower part

of the groove with a plastic comb or wooden

tongue depressor. Reinstall the porcelain insula-

tors. Push them flush against the furnace case.

They protect the element from contact with the

case, so they must not work their way out after

the element connector is tightened into place.

Sandpaper the eyelet of the element lead wires

if insulation on old ones is brittle. Use the brass

screw to connect lead wire eyelets to the new

element connectors.

Before tightening the screw, adjust eyelet to

where it will be tilted away from furnace case

when connector is attached to element. Then

hold the connector with pliers and tighten brass

screw securely with nut driver. Pull the end of the

element tight and install new element connectors

even against porcelain insulators to prevent in-

sulator from slopping away from brick wall. Use

stainless screw in the element connector to hold

the element. The brass screw holds the lead wire

eyelet.

Hold connector with pliers as you tighten the

screw. Tighten the screw until it squeaks, and

then tighten some more. Cut off twisted end of

element even with side of element connectors.

NOTE: Leaving the excess element sticking out past

element connector could ruin your new element!

The element can short against something in the

switch box.

As you move the switch box back into place,

check to see that no wire touches an element

connector. Wires and wire nuts must also not

touch the furnace case inside the switch box.

Wires and wire nuts will burn if they touch the

case or element connectors. Replace screws in

switch box and tighten into place.

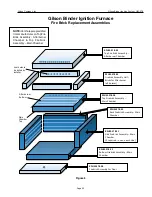

10.2.3 Replacing Afterburner Elements

The replacement elements for the furnace are made

to fit. However, a little stretching or compressing may

be necessary for a perfect fit.

NOTE: It is safe to bend and stretch new elements

before they have been fired, but once fired and

allowed to cool, elements become brittle and will

break if bent.

WARNING!

Disconnect and lockout electrical supply before

proceeding.

a. Allow the furnace to cool to room temperature.

b. Remove the screws on each side of switch box

and place the box to the side being careful not

to stress the wiring.

c. Remove the screws in the element connectors

that hold the element lead wires to the element

you are replacing.

d. On the same connectors, loosen the screws that

hold the element and throw old connectors away.

NOTE: ALWAYS use the new connectors furnished

with the new element.

e. Remove and save the porcelain insulators that

were under the element connectors.

f. Disconnect the power and conduit from the fan

by removing the access plate at the motor with

two screws. Remove the wire nuts and separate

the wires. Loosen the conduit clamp screws and

pull the conduit with wires from the fan.

g. Remove the 12 sheet metal screws holding the

fan and shroud to the top plate of the furnace.

Remove the fan assembly from the furnace.

h. Remove the ten screws holding the top metal

plate to the top of the furnace and remove the

top plate.