Gilson's Porta-Screen

®

5

.

The.Porta-Screen®.will.not.clamp.or.operate.properly.un-

less.fully.loaded.with.trays..If.your.test.requires.fewer.trays.

than.the.capacity.of.the.Porta-Screen®,.you.may.insert.the.

required.trays.in.the.upper.slots.with.the.pan.immediately.

below..Then.fill.the.lower.slots.with.extra.trays.

3.. Clamp.the.trays.by.rotating.the.clamp.levers.so.that.they.

point.down.

4.. Pour. your. sample. into. the. top. tray.. Refer. to. the. sample.

capacity.information.and.be.sure.not.to.overload.the.Por-

ta-Screen®.

5.. Connect. the. three-pronged. plug. into. a. properly-wired,.

grounded.receptacle.with.appropriate.electrical.current.

6.. Set.and.activate.the.timer.

7.. When. the. machine. stops,. unclamp. the. trays. by. rotating.

the.clamp.levers.so.they.point.up...Remove.and.empty.the.

trays,.following.the.directions.in.the.test.specifications.

8.. When.you.have.finished.the.test,.unplug.the.machine...Do.

not. reconnect. power. until. you. are. ready. to. use. the. ma-

chine.again.

9.. Store. clean,. empty. trays. in. the. unit,. leaving. them. un-

clamped.

10.. Re-level.the.machine.before.the.next.use.

3.0 SAMPLE CAPACITY

Capacity.of.the.Porta-Screen®.depends.on.the.specifications.

of.the.test.and.the.type.and.size.of.the.material.being.tested..

For.any.given.sample,.the.Porta-Screen's.maximum.capacity.

is.determined.by.the.tray.which.has.the.largest.load.at.the.end.

of.the.test..This.is.the.limiting.tray.

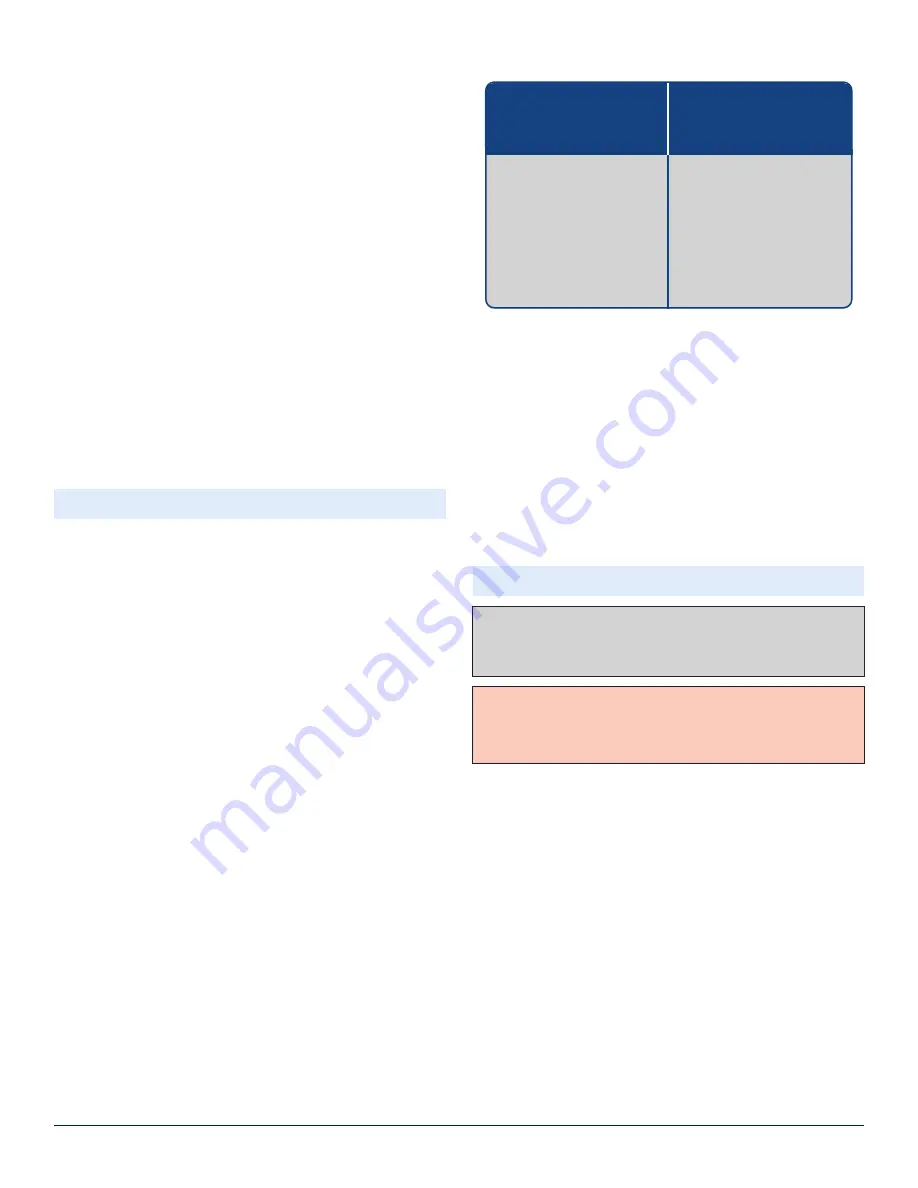

3.1 COARSE AGGREGATE

Minimum. quantity. of. sample. is. usually. established. by. the.

specifications. of. the. test. procedure.. . For. example,. ASTM.

C136. "Specification. for. the. Sieve. or. Screen. Analysis. of. Fine.

and.Coarse.Aggregates".calls.for.the.minimum.weight.of.the.

test.sample.of.coarse.aggregates.(density.such.as.limestone.

or.gravel).as.follows:

. These. guidelines. on. minimum. sample. size. quantities. are.

for. representative. samples.. Always. take. a. much. larger.

amount,. perhaps. from. several. spots. in. a. storage. bin. or.

stockpile.. Then. combine. and. reduce. them. to. the. correct.

quantity.by.splitting..

. With.coarse.series.trays.(2in–No.4),.the.limiting.tray.should.

have.no.more.than.one.layer.of.particles.over.the.wire.cloth.

at.the.end.of.the.test..Therefore,.lightweight.aggregates.or.

coal.must.be.tested.in.lower.sample.weights..High-density.

ores.or.pellets.may.be.tested.in.larger.amounts.by.weight..

Many. light. materials. are. also. soft,. and. test. times. should.

be.limited.to.avoid.degradation.of.the.sample.

. Most. samples. of. up. to. 2in. topsize. can. be. handled. in. a.

single.batch.without.difficulty..We.do.not.recommend.the.

use.of.trays.with.mesh.sizes.above.1.5in,.since.larger.par-

ticles.become.wedged.in.the.mesh.and.make.it.difficult.to.

remove.the.trays.

3.2 FINE AGGREGATES

With.fine.series.trays.(No.8–200),.the.limiting.tray.should.con-

tain.no.more.than.approximately.4g.per.square.inch.of.sieve.

surface. at. the. end. of. a. test.. Assuming. that. the. material. is.

about. the. density. of. sand,. there. will. be. approximately. 800g.

maximum.on.the.limiting.tray.

Since. the. Porta-Screen®. is. designed. primarily. for. use. in. the.

2in–No.20.range,.separations.in.finer.sizes.will.not.be.as.pre-

cise..If.you.are.testing.materials.exclusively.in.the.fine.range,.

we.recommend.equipment.specifically.designed.for.this.pur-

pose,.such.as.the.SS-8R.Gilson.8in.Tapping.Sieve.Shaker.

4.0 MAINTENANCE & DISASSEMBLY

NOTE:

Please read and understand all safety and main-

tenance instructions for the Gilson Porta-Screen® before

performing maintenance on it.

WARNING

Always disconnect and lock out electric power

before performing maintenance!

4.1 CLAMPING SYSTEM

1.. DISCONNECT.AND.LOCK.OUT.ELECTRIC.POWER.

2.. Load.the.Porta-Screen®.with.trays.and.a.pan,.filling.all.the.

slots.

3.. Rotate.the.Clamp.Levers.(38).so.that.they.point.down.

4.. Locate. the. Clamp. Adjusting. Nuts. (9),. which. are. on. the.

lower.ends.of.the.four.Clamp.Tension.Rods.(7).

5.. Tighten. the. nuts. only. enough. to. prevent. the. trays. from.

rattling.when.the.machine.is.operating.

4.2 LUBRICATION

1.. DISCONNECT.AND.LOCK.OUT.ELECTRIC.POWER.

2.. Remove.and.set.aside.trays.and.a.pan.

3.. Remove.upper.case.cover.

4..

Connection Rod Bearing:

Lubricate.the.Connecting.Rod.

Bearing.(52).after.every.80–100.hours.of.operation.

Normal Maximum

Minimum

Size of Particle

Sample Weight

mm (in)

kg (lb)

9.5 (3/8)

1 (2)

12.5 (1/2)

2 (4)

19.0 (3/4)

5 (11)

25.0 (1)

10 (22)

38.0 (1.5)

15 (33)

50 (2)

20 (44)

63.5 (2.5)

35 (77)