2-5

Installation

2

Z-Arm Installation

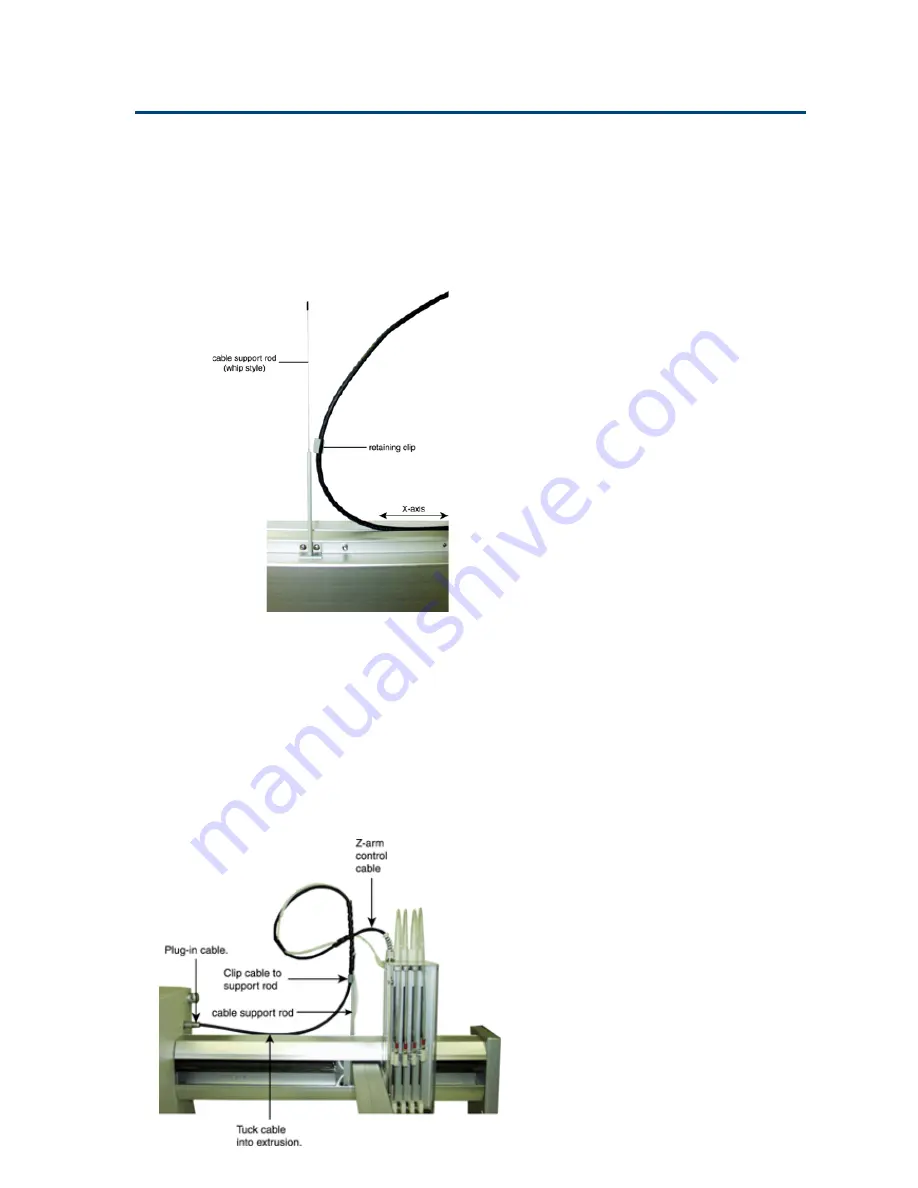

Installing the Z-Arm Cable Support Rod

1 Using the two Phillips screws, attach the cable

support rod bracket in the holes located in the

rear of the X-arm extrusion.

2 Extend the arm to the extreme X- and Y-direction

to ensure that the cable will have enough slack.

Plug the Z-arm control cable into the back topside

of the control cabinet. The control cable should be

tucked into the groove located in the top of the

X-arm extrusion. The retaining clip that is already

on the control cable should be snapped onto the

top of the cable support rod. Refer to diagram

below.

Summary of Contents for Quad-Z 215

Page 1: ...Quad Z 215 Liquid Handler User s Guide LT2545 2003 Gilson Inc All rights reserved April 2003...

Page 2: ......

Page 6: ......

Page 8: ......

Page 15: ...1 7 Introduction 1 Technical Specifications...

Page 16: ...1 8 Introduction 1 Technical Specifications...

Page 72: ......

Page 73: ...5 1 5 Troubleshooting...

Page 82: ......