6

De

cr

ea

se

In

cr

ea

se

+

ALLUMINI OXIDE CAPSULE

PRODUCT NO: IM-CAP-003

LOT NO: 20050219

Before You Begin

• Read all these instructions prior to operation.

• Carefully remove the system from the shipping box and foam packing.

• Remove the plastic covering and place machine on a hard flat surface.

• Unpack the Crystal Capsule

™

, handpiece and tubing.

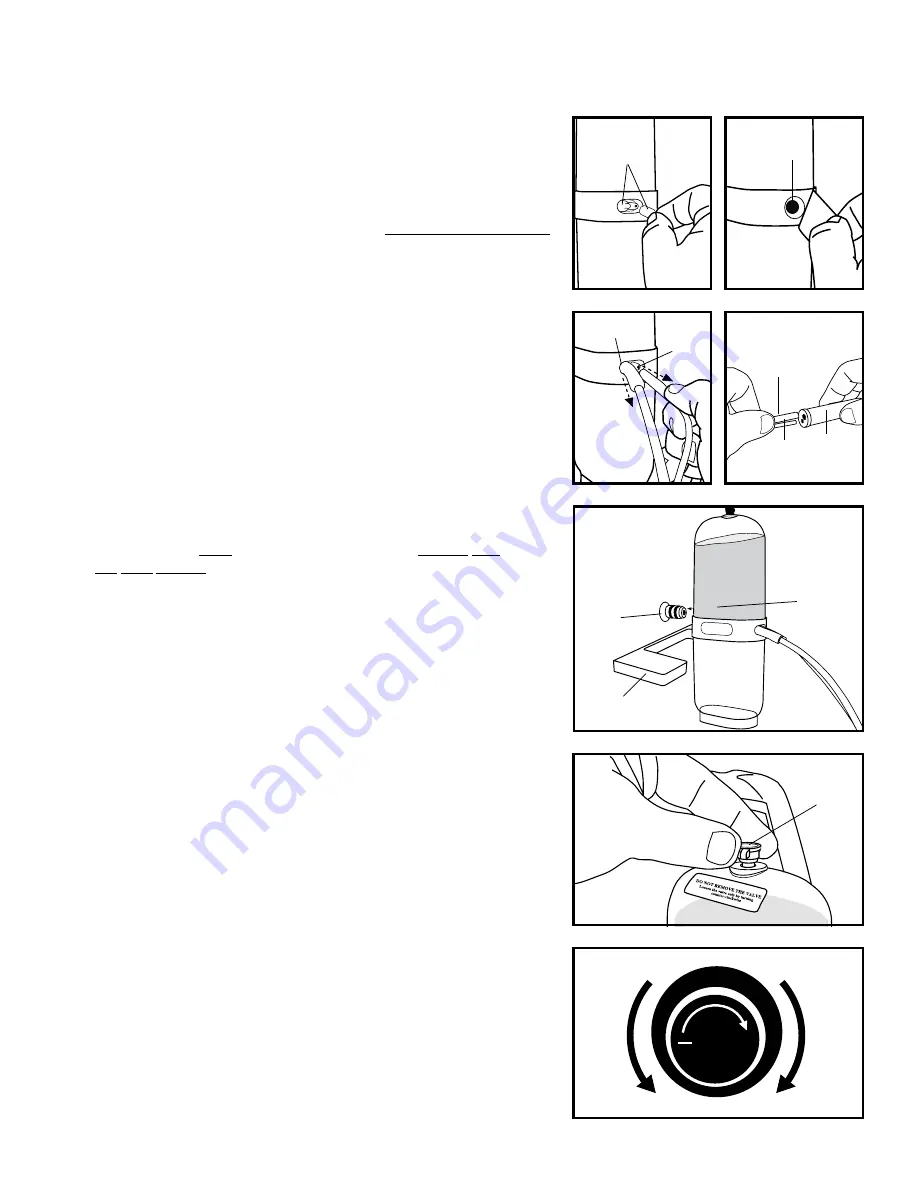

• Remove the 2 rubber caps from the port posts. Do not discard rubber caps.

You will need the rubber caps to plug the port posts when disposing of used

capsule (fig. 4).

• Hold capsule upright. Remove the label covering vacuum hole (fig. 5).

Attaching the Tubing & Nozzle

• Connect the proper size tubing to the appropriate post on the capsule. Push

tubing firmly onto the posts (fig. 6).

• Connect the proper size tubing to the flat end of the nozzle. Push tubing firmly

into the nozzle (fig. 7).

Attaching the Media Canister

• Slide the Crystal Capsule’s

™

opening onto the male vacuum port post sticking

out of the front of your Gio Peel. Vacuum port post is located between the

Crystal Capsule

™

stabilizer (fig. 8).

•

Wipe post clean

prior

to inserting. Be sure you slide

straight

onto

the post.

DO

NOT

TWIST

or you will damage the

sealing o-rings

.

• Insert capsule fully onto the post with both o-rings down inside the opening

in the capsule.

Turning the Unit On

• Place the master power switch on the side of the unit in the

OFF

position.

• Plug the

POWER CORD

into the connector located on the back of the

microdermabrader.

• Attach the other end of the

POWER CORD

to a properly grounded outlet

supplying 115vac.

• Depress the I portion of the master power switch located on the back of the

Gio Peel to turn the unit on. The fan will start.

• Depress the I portion of the power switch located on the front of the Gio Peel

to turn the suction on.

Adjusting Crystal Flow

• Unscrewing the nut counter-clockwise adjusts crystal flow. You should notice

some movement, or bubbling, of the new abrading media inside the Crystal

Capsule

™

when preforming procedures (fig. 9).

• If less crystal flow is desired, unscrew the nut until you see a slight decrease of

the crystal bubbling inside the capsule, or no movement at all which indicates

minimum volume of crystal flow (fig. 9).

Vacuum Control Valve

• Turn the Vacuum Control Valve clockwise to increase the vacuum or counter-

clockwise to decrease vacuum (fig. 10).

INSTALLATION & SET UP

Contact us if the unit fails to operate during these steps.

Figure 4

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Figure 10

Vacuum

Port

&

Sealing

O-Rings

Insert

Capsule

STRAIGHT

onto

Vacuum

Post

Rubber Caps

Vacuum Hole

Large

Tube

Small

Tube

Large Tube

Small

Tube

Nozzle

Capsule

Nut

Crystal Capsule

™

Stabilizer