Maintenance

142

Code no. 550038

Rev. no. 16/1018

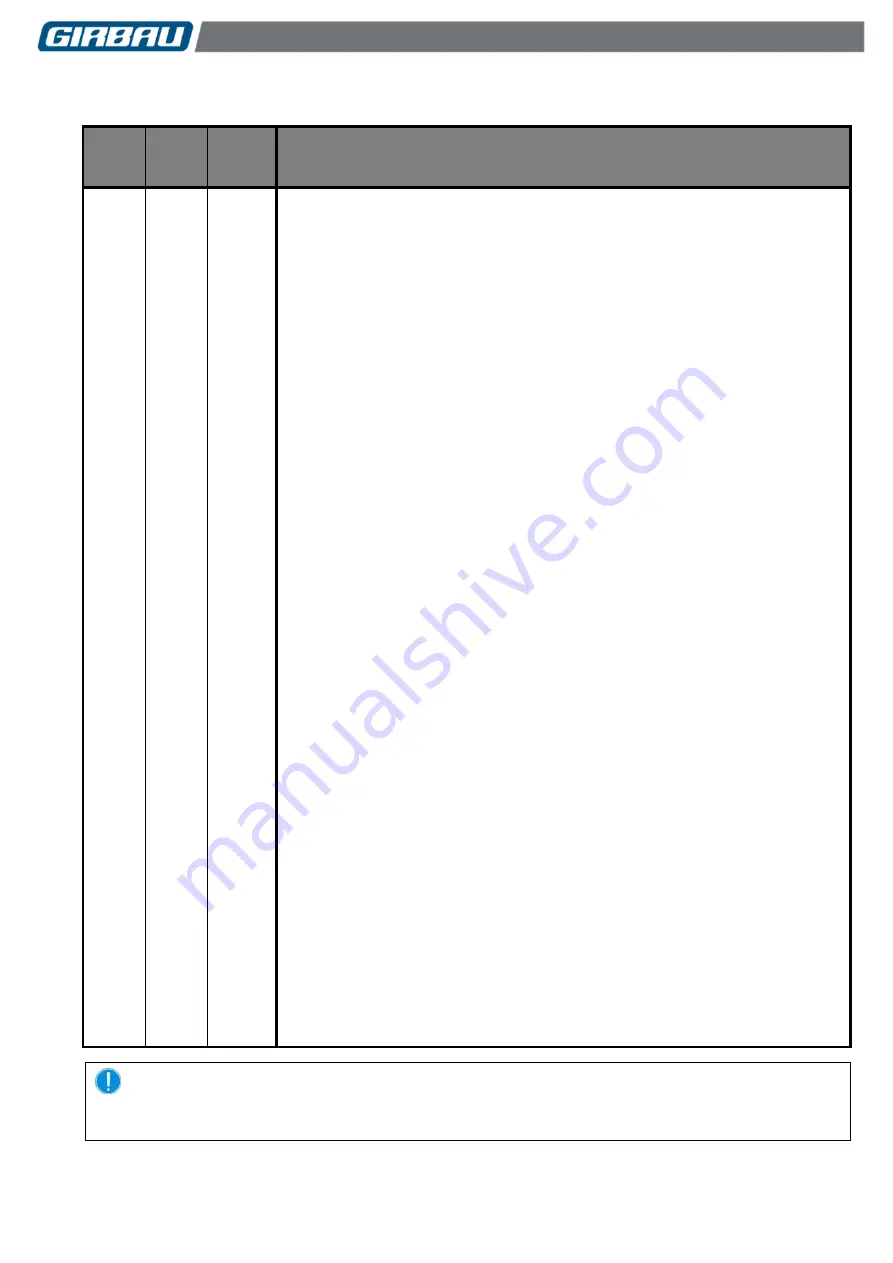

13.6. Preventative maintenance program

7DAY

50 h

QUAR

600 h

ANNUAL

2400h

PROCEDURES RESERVED EXCLUSIVELY FOR CUSTOMER’S TECHNICAL

SERVICES OR AUTHORISED TECHNICAL SERVICES

x

Check the contact of the temperature probe and thermostat with the roll

x

Check and clean the linen detachment tabs

x

Clean the primary air filters (gas heating)

x

Check the heating system ignition and combustion (gas heating)

x

Clean and check the exhaust filter

x

Clean the holes in the vapour suction pipe

x

Clean the photocell reflectors and the linen feed sensors. The number of

photocells and sensors varies depending on the models .(PBP51, X20***F

models)

x

Clean the protective vents of the roll motor and extraction motor fans

x

Lubricate the transmission chains and the rolls' support wheels

x

Check the condition of the ironing straps and the pressure roller padding

x

Clean the extraction turbine blades and the exhaust ducts

x

Clean the inside of the base-frames

x

Check the condition of the extractor roller tapes and rubber rollers (PBP51,

X20***F models)

x

Clean the steam inlet and condensate return filters (steam heating)

x

Check the static pressure at the fan output.

x

Clean the pressure switch circuit (PB/PBP51 models, AGA machines only)

REQUEST AN ANNUAL SERVICE FROM AUTHORISED TECHNICAL SERVICES

x

Check all the functions of the ironer (TEST program)

x

Check the heating system

x

Check the power consumption of the roll motor and the extraction motor

x

Check the power consumption of the electric heaters (electric heating)

x

Check and clean the burner (gas heating)

x

Check and clean the premixing fan (radiant burner)

x

Check the wear and contact of the detachment tabs

x

Check the ironing straps

x

Check the feeding straps

x

Check the output straps (PBP51 model with folder)

x

Check the pressure roller padding

x

Check and lubricate chains, sprockets, crown wheel race and roller supports

x

Check the coupling of the encoder or motion detector

x

Check linen detachment tapes

x

Check the condition of the extractor roller tapes and rubbers (model PBP51 with

folder)

x

Check external protections and electrical grounding

x

Check the condition of the roll

x

Checking the wear and contact of the thermostat probe runners

x

Check the gas tightness of the gas circuit (gas version)

x

Check the condition of the nuts and bolts

x

Check that the steam circuit is airtight (steam version), and check for possible

deterioration due to wear

x

Check the roll motor and extraction motor

x

Clean all soot and fluff from the inside of the roll and areas of the machine involved

in the extraction of fumes and vapours

CAUTION!

Lubricate only the points described in the section entitled Preventive maintenance program. For any questions

about maintenance please contact the manufacturer.