Steps for the connection

61

Code no. 550038

Rev. no. 16/1018

5.2.1. Installation characteristics

See the

Technical and Connection Details

for the

corresponding model (Chapter 4) for values regarding

connection pressure, power consumption, and the diameter

and position of the connection.

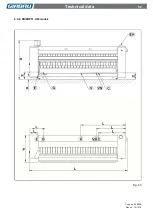

PB32, X13. Gas connection

Fig. 5.7

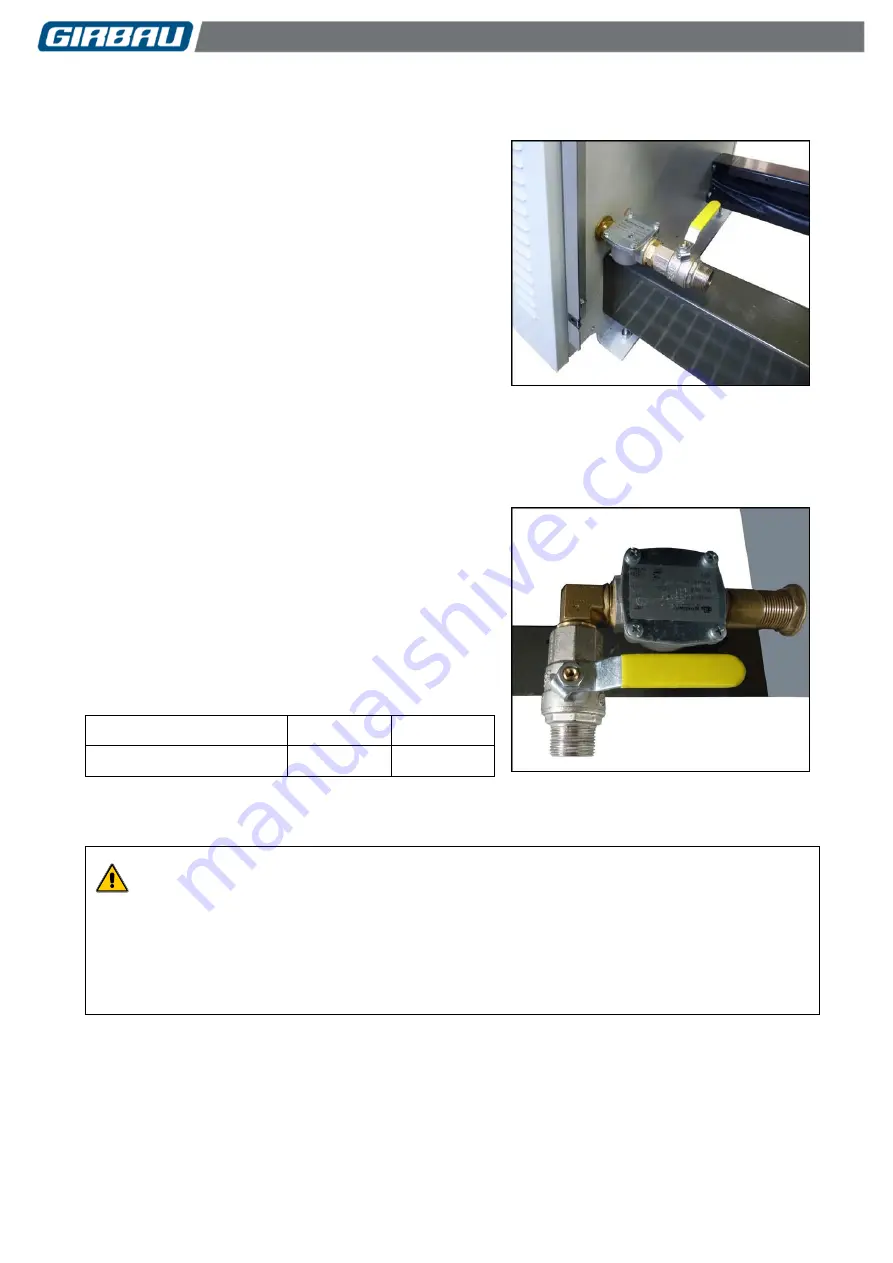

PB/PBP51, X20. Gas connection

Fig. 5.8

Installation requirements

In order to ensure the supply pressure indicated, both at the

input of the regulator and the input of the machine, it is

recommended to:

Install a pressure regulator capable of supplying the

required flow, and fit a pressure gauge to the regulator

inlet and outlet.

Ensuring that the gas conducting pipe is of a sufficient

size.

Avoiding, if possible, the use of flexible joints.

As protection for the burner, it is recommended to

install a device to protect against excess pressure.

5.2.2. Connecting the machine to the supply network

The connection should be made at the input to the burner,

located at the rear of the machine (Fig. 5.7 and 5.8).

The machine intake connection pipe is:

CE

certified models.

BSP

thread

3/4 in

ETL

certified models.

NPT

thread

3/4 in

DANGER!!

IN ANY OPERATING CONDITION, THE PRESSURE OF THE GAS SUPPLY ENTERING THE IRONER

MUST CORRESPOND TO THE PRESSURE INDICATED IN SECTIONS 4.3, 4.4 AND 4.5 OF THIS

MANUAL. PRESSURES OTHER THAN THOSE INDICATED MAY CAUSE THE IRONER TO

MALFUNCTION AND PRESENT A RISK OF SERIOUS INJURY.

THE MANUFACTURER DECLINES ALL RESPONSIBILITY IN THESE CASES.