18

Swiss Lifting Solutions

Designation

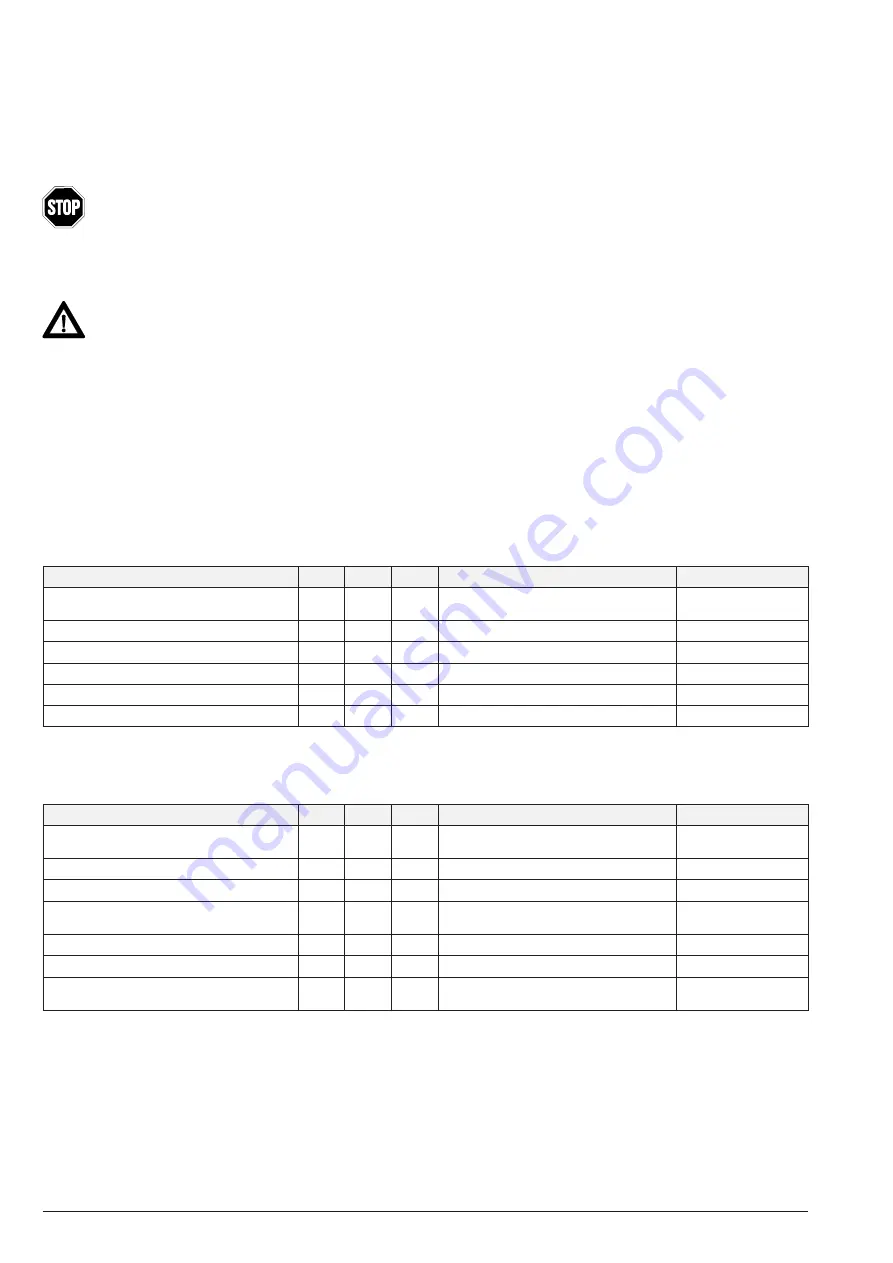

d

3 M

12 M Task

Remark

1. Load chain

x

x

Oil

Measure wear

see chapter

2.2.2 / 3.2.4

2. Brake system

x

x

Function check with load

see chapter 3.2.3

3. Electrical equipment

x

Function check

4. Fixing screws on suspension parts

and load hook with accessories

x

Check for cracks

Check screw torque

see chapter 3.2.8

5. Limit switch

x

Check switching elements

see chapter 2.2.3

6. Slipping clutch

x

Function check

see chapter 3.2.7

7. Leaktightness

x

Check screw torques of the covers

Check cable glands

see chapter 3.2.8

3.2.2 Maintenance overview

Table 3-2 Maintenance overview

Designation

d

3 M

12 M Task

Remark

1. Load chain

x

Visual check

Clean and lubricate as needed

see chapter 2.2.2

2. Lifting device and trolley

x

Check for abnormal noise / sealing

3. Electric power supply cable

x

Visual check

4. Limit switch

x

Function check

see chapter 2.2.3

5. Sealing

x

Visual check

6. Strain relief control cable

x

Visual check

3.2.1 Care overview

Table 3-1 Care overview

3.2 Care and maintenance

General:

Care and maintenance tasks are preventive measures designed to preserve the full functionality of electric chain hoists. Non-compliance

with care and maintenance routines can result in limited use and damage to electric chain hoists.

Care and maintenance should be carried out in accordance with the instruction manual at predefined time intervals (table 3-1 and 3-2).

During care and maintenance work, general accident prevention directions, special safety directions (chapter 0.3) as well as hazard pro-

tection instructions (chapter 0.4) should be followed.

Care and maintenance work should be performed only on electric chain hoists with no loads. The main switch must be off. The

hook fittings must lie on the ground or on the maintenance platform.

Care work encompasses visual checks and cleaning routines. Maintenance work includes additional functional checks. During the functio-

nal checks, all fixing elements and cable clamps must be checked for tightness. Cables must be inspected for dirt, discolouration and arc

spots.

Used operating materials (oil, grease, etc.) should be safely collected and disposed of in an environmentally friendly manner.

Care and maintenance intervals are defined as follows:

d (daily), 3 m (quarterly), 12 m (annually)

The predefined care and maintenance intervals should be reduced when the loading of the electric chain hoist is exceptionally large or

when frequently operated in adverse conditions (e.g. dust, heat, humidity, steam, etc.).