Handling instructions

for GISMA connectors

HI

– 2007 - 001

Document: replaces

MV 2000-020,

MV 2000-030 and

MV 2005 - 011

First issue:

15.07.2008

Rev.-Index: -Z-

From:

29.07.2020

Copyright by:

GISMA GmbH

Page 6 of 44

7. DEPLOYMENT & MAINTENANCE

The following section details deployment and maintenance instructions for all GISMA connectors &

cables, categorised by product type. Please refer to the appropriate section as listed below:

7.1. - Subsea connectors

’ series 10

7.2. - Subsea

connectors’ series 16

7.3. -

Subsea connectors’ series 22

7.4. -

Subsea connectors’ series 34

7.5. -

Subsea connectors’ series 35

7.6. - Subsea

connectors’ series 40

7.7. -

Subsea connectors’ series 42

7.8. -

Subsea connectors’ series 80

All information contained within this section is generic. Where customer or project-specific

information is required, please refer to the relevant project specification or scope of supply.

For further technical information refer to the catalogues of the different series or special drawings.

Note: It is important to isolate and earth prior to disconnect in order to remove any stray

charges in the system. If left, this can induce corrosion on the exposed pins once the plug is

removed.

The connector shall have the following periodic maintenance checks:

Examine the connector for signs of damage.

Check the locking sleeve, these shall be tight, if loose refer to assembly instruction

for torque values, where appropriate.

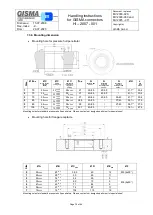

SUBSEA CONNECTORS SERIES 10

7.1.1. General

The series 10 sizes 1 to 7 range of connectors has been developed for long term reliable signal

and low power control system applications associated with offshore installations. The underwater

mateability of the range of signal connectors series 10 (contact-Ø 1mm and 1,5mm) is achieved

by using a patented, conical sealing system at each contact and a lip gasket.

For further technical information refer to the catalogue of series 10 or special drawings.

The connector range series 10 comprises standard

power connectors

for high voltage and high

current application as well.

NOTE!

These connectors are not underwater pluggable. Please ask

for detailed product information.

Connectors are usually supplied with dust caps. The dust caps need to be removed prior to mating

the connectors.

All mild steel sealing interfaces shall be inlayed with Inconel 625, or similar, where no additional

protection can be provided. This is to prevent localised pitting of the interface. If not possible

grease the mounting hole and the supporting surface with corrosion preventing fluid (for example

Fluid Film) as a minimum.