Handling instructions

for GISMA connectors

HI

– 2007 - 001

Document: replaces

MV 2000-020,

MV 2000-030 and

MV 2005 - 011

First issue:

15.07.2008

Rev.-Index: -Z-

From:

29.07.2020

Copyright by:

GISMA GmbH

Page 12 of 44

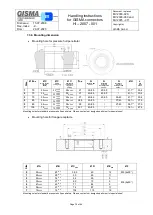

SUBSEA TITANIUM CONNECTORS SERIES 16

7.2.1. General

The series 16 sizes 3,4,5,6 ranges of connectors has been developed for long term reliable signal

and low power control system applications associated with offshore installations.

The long term watertightness of the mating area at the signal connectors series 16 (contact-Ø 1,5

mm) is achieved by using a patented, conical sealing system at each contact, a lip gasket and an

O-ring seal.

NOTE!

These connectors are

not underwater mateable

.

A part of series 16 connectors are especially designed for oil compensated systems and are

pressure proof from both sides.

NOTE!

Please make sure to use the appropriate connector in your system.

For further technical information refer to the catalogue series 16 or special drawings.

Connectors are usually supplied with dust caps. The dust caps need to be removed prior to mating

the connectors.

All mild steel sealing interfaces shall be inlayed with Inconel 625, or similar, where no additional

protection can be provided. This is to prevent localised pitting of the interface. If not possible

grease the mounting hole and the supporting surface with corrosion preventing fluid (for example

Fluid Film) as a minimum.

If the connectors are to be left unmated in seawater for any length of time, pressure watertight

protective caps must be used to protect the contacts. Over exposure will increase the risk of

corrosion damage or marine growth on the contact surfaces of the pin contacts. This could lead

to damage to the seals and insulation within the socket contacts.

The appropriate test connector must always be used to make electrical contact during testing.

UNDER NO CIRCUMSTANCES

should a foreign object (such as a screwdriver, test probe or

crocodile clip) be used as a test connection as this could damage the seals and insulation. Such

actions will invalidate the warranty of the connector.

Attention: The customer is responsible for the safe operation of the connectors and cable

systems. All necessary protective measures must be taken.

Test connectors or free touchable connectors with metal shell must be connected to the

earth conductor.

The series 16 range of connectors can be supplied either singularly or as part of a harness

assembly. All series 16 connectors require the following acceptance tests during termination:

Mating test

Insulation Resistance test

High Voltage test

Continuity test

Cable terminations can be performed on-site or offshore by GISMA trained personnel where the

cable cannot easily be moved or transported. Each series 16 connector has been mated,