Handling instructions

for GISMA connectors

HI

– 2007 - 001

Document: replaces

MV 2000-020,

MV 2000-030 and

MV 2005 - 011

First issue:

15.07.2008

Rev.-Index: -Z-

From:

29.07.2020

Copyright by:

GISMA GmbH

Page 4 of 44

GISMA ELECTRICAL & FIBRE OPTIC CONNECTORS -

PROTECTION, STORAGE, SHIPMENT, UNPACKING,

DEPLOYMENT & MAINTENANCE INSTRUCTIONS

1. GENERAL

Thank you for purchasing a GISMA product. The information that follows is an overview of the

protection, storage, shipment, unpacking, deployment and maintenance instructions for GISMA

electrical and fibre optic products.

GISMA recommend the termination and handling of all equipment only be undertaken by suitably

trained and qualified personnel.

2. SCOPE

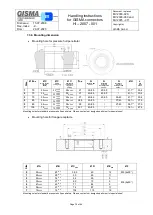

This procedure includes information on the following connector types:

GISMA series 10

GISMA series 16

GISMA series 22

GISMA series 34

GISMA series 35

GISMA series 40

GISMA series 42

GISMA series 80

Sections 3, 4, 5 and 6 handle general information applicable to all GISMA connectors. Section 7

then provides specific information relevant to each connector series.

3. PROTECTION, HANDLING AND SHIPMENT

GISMA electrical, fibre and hybrid connectors are manufactured primarily from materials such as

stainless steel 1.4404 / 1.4571 (316L / 316Ti), marine bronze (CW307G) and titanium Grade 5, and

as such are designed to withstand harsh saliferous environments. However, the connector insulator

and exposed parts are susceptible to mechanical damage if not adequately protected. Dust caps are

fitted to all GISMA connectors before transport, but can be fitted with POM protective caps or

pressure watertight protective caps, if specified by the customer. Pressure watertight caps must

remain in place until the connectors are ready for the underwater mating process.

The connectors are generally relatively small items of equipment, and therefore, can be shipped

singularly or in multiples. Care should be taken to protect the connector with bubble wrap or similar

wrapping materials to avoid surface damage during transit. Dust caps or POM protective caps must

be fitted at all times during transport.

If the connectors are assembled onto cables these must be suitably coiled and secured with

appropriate material (tape, cable strap) to prevent uncoiling during transit. Recommended bend

radius for storage/transport of cables, refer to cable specification or jumper drawing.

Any connector-specific handling and transport advice is contained within the appropriate section

further on in this document.