39

24.0_TROUBLE SHOOTING (ADVANCED)

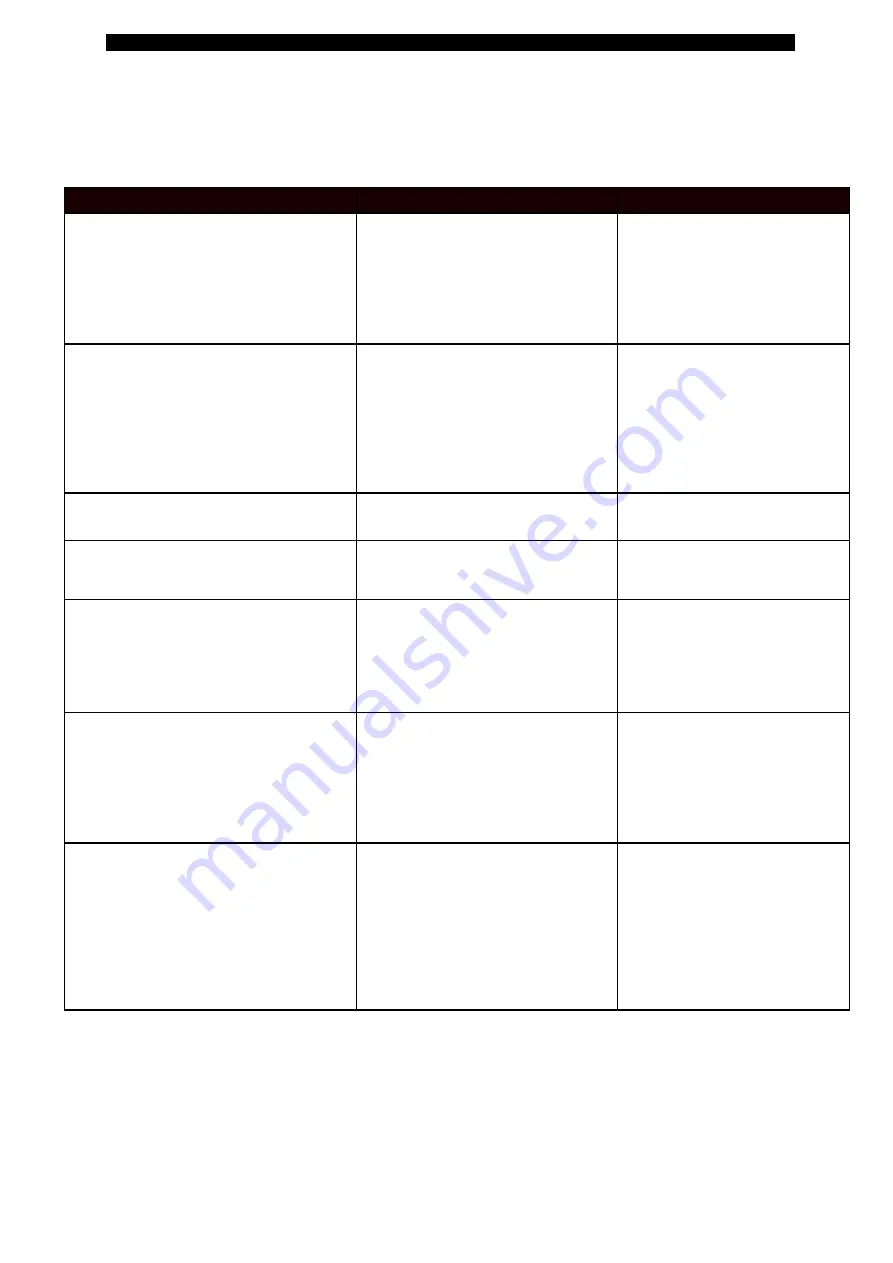

OPERATING ANOMALIES

PROBLEM

CAUSE

I

SOLUTION

The self-centring chuck does not turn

1) No electrical power supply

2)Power supply plug not plugged-in

correctly

3)Fuses blown

4)Belt loose or broken

5)Motor pulley loose

1) Check the socket on the wall

2) Plug the machine into the

mains

3) Replace the fuses

4) Tension the belt or replace it

5)Tighten the pulley with the

dedicated screw

The spindle rotation motor only runs at

one speed

1) Inverter broken

2) Inverter cables disconnected

3) Motor broken

4) Motor cables disconnected

1) Replace the inverter

2) Check if the inverter cables

are connected correctly

3) Check motor short-circuiting

and replace

4) Check if the motor cables are

connected correctly

The spindle turns continuously

1) Inverter broken

2) Pedal return spring broken

1) Replace the inverter

2) Replace the spring

The spindle turns but the wheel stays still 1) Clamping screw not holding

2) Anti-rotation pin not holding

1) Secure the screw correctly

2)Position the driving pin cor

-

rectly

The bead breaking disc does not move

vertically or it moves slowly

1) No pneumatic supply

2) Control valve broken

3) Silencers obstructed

4) Cylinder gasket broken

5) Pilot valve broken or malfunctio

-

ning

1) Check the line pressure

2) Replace the valve

3) Clean the silencer or replace it

4) Replace the gaskets

5) Replace the pilot valve

The bead breaking disc does not move

horizontally or it does but very slowly

1) No pneumatic supply

2) Control valve broken

3) Silencers obstructed

4) Cylinder gasket broken

5) Pilot valve broken or malfunctio

-

ning

1) Check the line pressure

2) Replace the valve

3) Clean the silencer or replace it

4) Replace the gaskets

5) Replace the pilot valve

The bead breaking disc positions itself but

does not make the over stroke movement

1) No pneumatic supply

2) Control valve broken or malfun

-

ctioning

3) Cylinder gaskets broken

4) Movement not activated

5) Over stroke activation switch

broken

6) Pilot valve broken or malfunctio

-

ning

1) Check the line pressure

2) Replace the control valve

3) Replace the gaskets

4) Turn the switch

5) Replace the switch

6) Replace the pilot valve

Summary of Contents for Crossage

Page 1: ...Original Instructions Ed 01 11 Cod 3019988 Use and Maintenance instruction manual...

Page 41: ...41 WIRING DIAGRAMS...

Page 42: ...42...

Page 43: ...43...

Page 44: ...44 PNEUMATIC DIAGRAMS...

Page 45: ...45 Optional...

Page 46: ...46...

Page 47: ...47 SERVICE REGISTER...