16

Routine maintenance according to the following instructions is of crucial importance to ensure the correct operation and

lasting life of the Tyre-Changer.

The Manufacturer is not responsible for claims due to non-original spare parts or for damages caused

by removal and tampering to the safety devices.

Removal or tampering with the safety devices (max. pressure valve – pressure regulator) represents a

breach of European Regulations for Workplace Safety.

- Non-routine maintenance must be carried out by factory authorized personnel ONLY.

- Defective parts should be exclusively replaced with genuine spare parts by factory authorized service

personnel.

- After 5 years from installation date, the Tyre-Changer must be serviced in all its main components to grant its

correct functioning and the operators safety.

19.1 Standard Maintenance

19.0 MAINTENANCE

Before starting any maintenance job, disconnect the electrical power supply by unplugging the machine

from the main electrical feeding and disconnect it from the pneumatic supply by shutting off the valve.

To release the compressed air from the circuit, press the inflation pedal (ref.

23

at page 24) down for a few

seconds.

On daily basis, keep the machine clean eliminating any mould and dirt to ensure the perfect movement

of the slides and the tools and to grant the correct functioning of all centering and locking systems.

Do not clean with compressed air, which can blast dirt between moving parts.

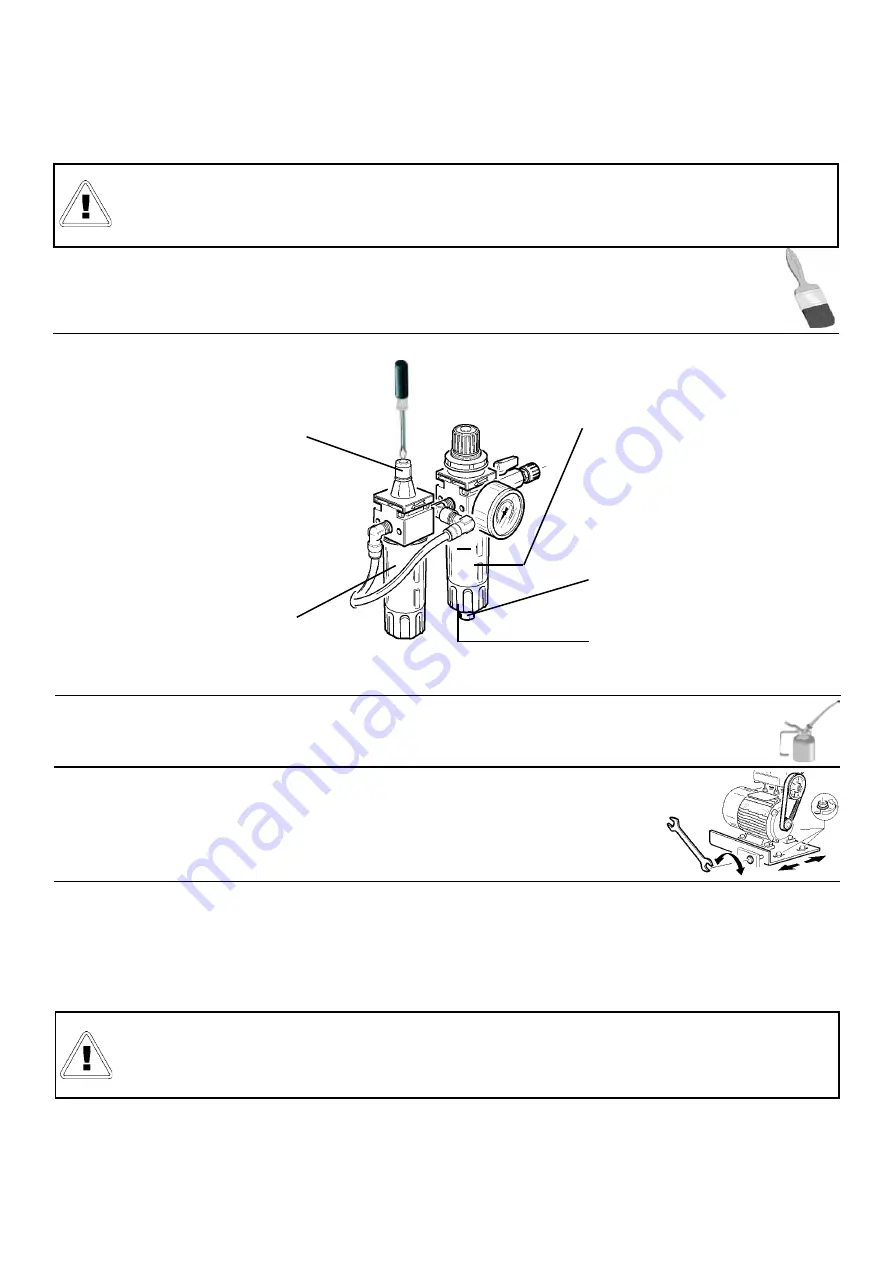

Every 2/3 days, check the oil dropping

into the cup (1 drop every 4/5 activa-

tions of the bead pressing tool or of the

bead loosening systems). If necessary,

turn the screw on the top of the cup by

a screwdriver.

On periodical basis, check the oil level

which has to keep between MIN and

MAX refs. If necessary, unscrew the

cup and top-up by adding oil for pneu-

matic systems in class ISO HG (i.e.

ESSO Febis K32; MOBIL Vacouline

Oil 1405; KLUBER Airpress 32).

For a long lasting correct functioning of

the 10bar pressure limit device, ensure

that the drain level doesn’t exceed the

MAX DRAIN indication

If necessary, drain the condensation by

turning clockwise the drain tap. (keep

the pneumatic feeding on to perform

this adjustment).

Max

Drain

On monthly basis, unplug the machine

from pneumatic feeding and remove

the filter cup to clean it from possible

solid impurities.

On periodical basis, clean the sliding guides of the bead loosening carriage by naphtha and lube them

by oil or proper grease. Perform the same cleaning and lubricating actions on every junction and

mechanical sliding.

On periodical basis, check the tensioning of centre-plate rotation driving belt. If necessary, use

a 13mm wrench to loosen the fixing bolts of the motor support plate, then adjust the belt tension

by acting on the tensioning screw and tight the fixing bolts.

19.2 Extraordinary maintenance