3

CONTENTS

CHAPTER

Page

1.0

INTRODUCTION......................................................................................................................................................4

1.1 Tyre-Changer data...............................................................................................................4

1.2 Manufacturer data............................................................................................................................4

1.3 Data plate.........................................................................................................................4

2.0

GENERAL DESCRIPTION...........................................................................................................................4

3.0

SPECIFICATIONS...........................................................................................................................5

4.0

DECALS PLACEMENT.................................................................................................................................6

5.0

SAFETY INSTRUCTIONS............................................................................................................................7

6.0

SAFETY DEVICES....................................................................................................................................7

7.0

TRANSPORT.........................................................................................................................................................8

8.0

UNPACKING.......................................................................................................................................................8

9.0

INSTALLATION....................................................................................................................................................9

9.1 Tyre-Changer site requirements.................................................................................................................9

9.2 Tyre-Changer placement and connections.............................................................................................9

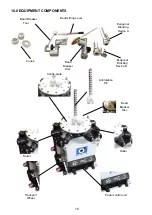

10.0 EQUIPMENT COMPONENTS............................................................................................................................................10

11.0 CONTROLS DESCRIPTION.......................................................................................................................11

12.0 TYRE DEMOUNTING...............................................................................................................12

13.0 TYRE MOUNTING.......................................................................................................................................13

14.0 STANDARD ACCESSORIES............................................................................................................................14

15.0 RE-POSITIONING................................................................................................................................................15

16.0 STORAGE................................................................................................................................................15

17.0 SCRAPPING................................................................................................................................................15

18.0 OIL TREATMENT................................................................................................................................................15

19.0 MAINTENANCE................................................................................................................................................16

19.1 Standard maintenance......................................................................................................................16

19.2 Extraordinary maintenance...............................................................................................................................16

20.0 TROUBLESHOOTING CHART.........................................................................................................................................17

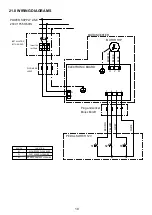

21.0 WIRING DIAGRAMS..............................................................................................................................................18

22.0 PNEUMATIC DIAGRAMS.................................................................................................................................................19

23.0 SERVICE REPORTS.......................................................................................................................................................20