USER MANUAL

DIGITAL READOUT VISION 518

MT02_A31_B_VI518_GIVI_ENG rev. A

Pag. 18/32

The linear correction has the following characteristics:

1. it is permanently stored (it becomes a mechanical component of the axis);

2. it can always be modified, entering other

CF

values. The permitted values are:

MIN

= 0.000001

TYP

= 1.000000

MAX

= 9.999999

3. it can be disabled entering

CF = 1

or deleting the linear correction with the function

F 00

;

4. it has priority over preset, reset, etc. functions.

The correction must be entered before the other functions (which otherwise

would be modified).

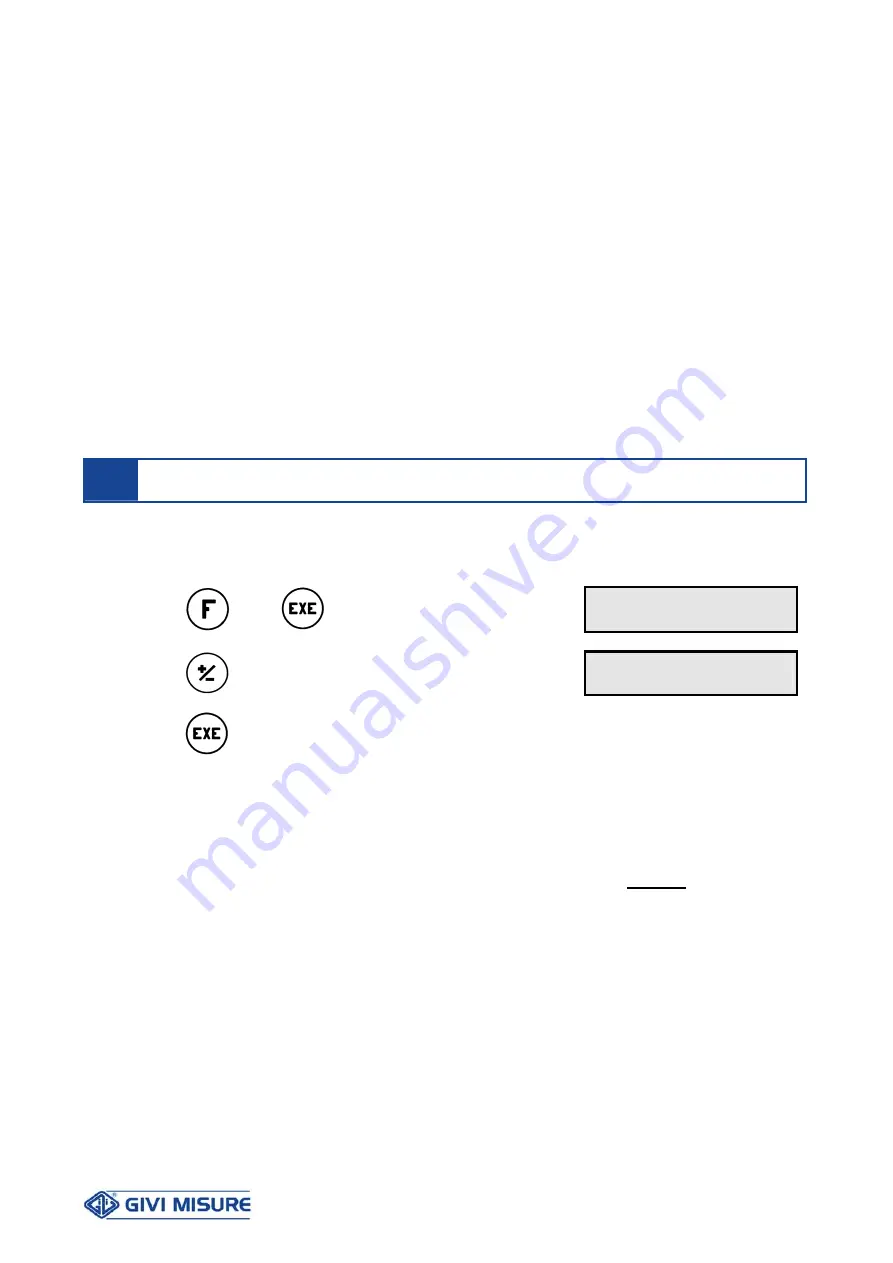

The function can be used to select the required reading mode.

Press

3 4

r A d .

Press

to select

°

d i A .

Press

to confirm the selection.

After having confirmed with the EXE key, the display will be enabled for counting.

While choosing the reading mode, consider that:

A) RADIAL READING:

the display shows the same value of the carriage

movement. This is the most common reading mode.

B) DIAMETRAL READING:

the display shows a value that is the

double

of the carriage

movement. This reading mode is typically used for the

transversal axes of lathes. In fact, if the tool advances by

1 mm, the workpiece diameter decreases by 2 mm.

1.

The unit of measurement can be switched from MM to INCHES and vice versa in

both reading modes.

2.

A permanently lighted point on the first digit signals that the axis is set in diametral

reading.

3.

Any previous RELAY OUTPUT setting is disabled since it is altered by the reading

mode selected. On the contrary, the reference positions are retained.

RADIUS/DIAMETER CONVERSION

F 34