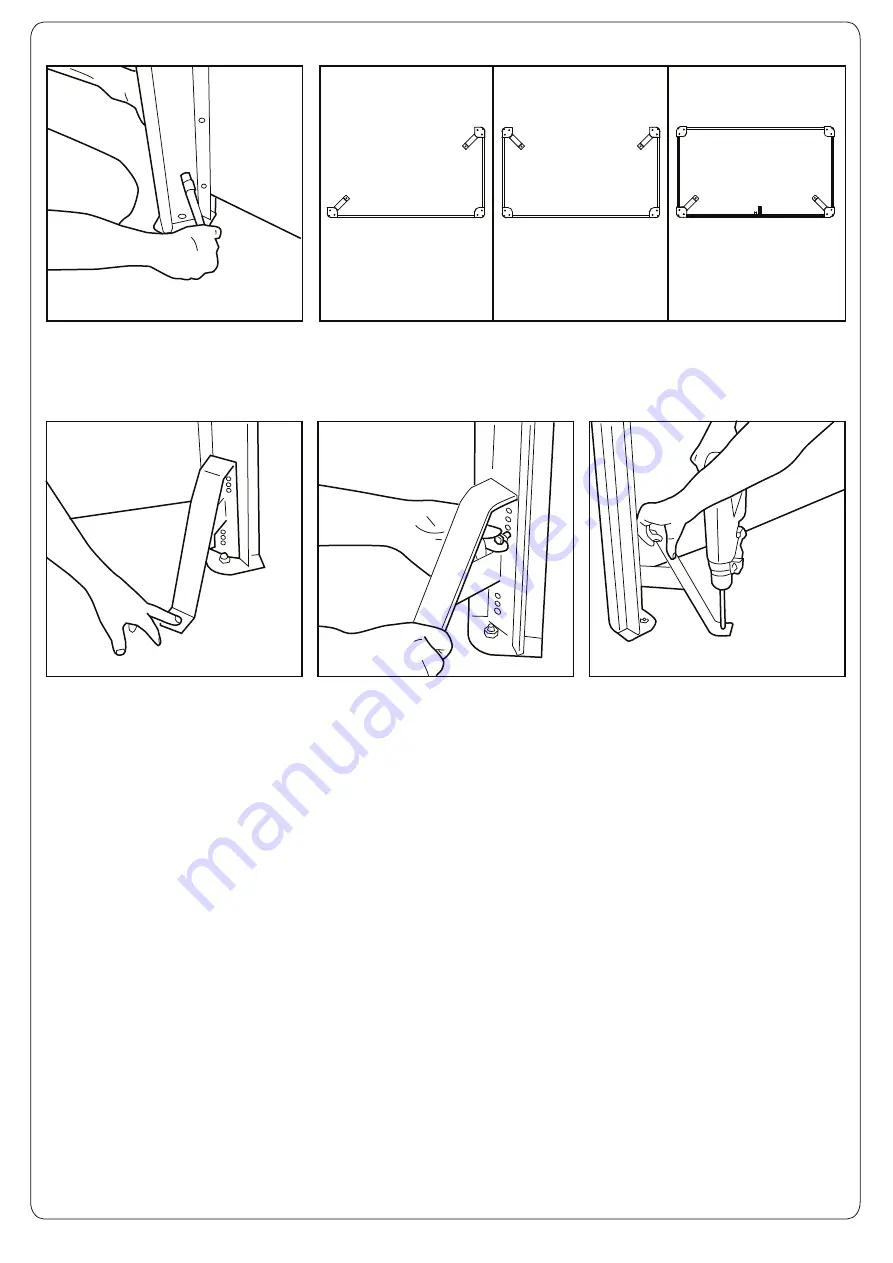

Using a 13mm spanner/socket unscrew the two bolts with washers at the bottom of the outermost

extrusions and remove. (see diagrams above showing location of support legs for all screen types) If the

spigot legs have been adjusted (Step 1) the panels will need to remain lifted in position so that the support

legs go into the correct holes. (may require two people.)

Place the support leg (B) up

against the inside of the extrusion

so that the leg protrudes outwards

and stands on the ground. If the

spigot legs have been adjusted

there are several pre-drilled holes

in the support leg to

accommodate this adjustment.

Replace the bolts and washers

into the new holes through the

support leg, extrusion and into

the spigot leg. Tighten with

13mm spanner/socket.

Concrete fix the support legs into

the ground as per Fig 10, 11 and

12 (Step 2).

Step 3: Attaching and Ground Fixing Compulsory Support Legs

13

14

15

16

P. 3

Two Sided

Three Sided

Four Sided c/w Door