Level Wind Reels

Best Management of Long Cables

Level Winding Reels have demonstrated through years of use to be the safest and most reliable way to handle long

lengths of large cable. By winding a single layer of cable horizontally on a generous drum diameter, the cable expe-

riences minimum flexing and is exposed to maximum cooling, should that be a concern. Equipment speeds can be

slow, moderate or high with equally good performance. Cable guide is included. Reels can be shipped complete with

cable installed, or site mounted by others.

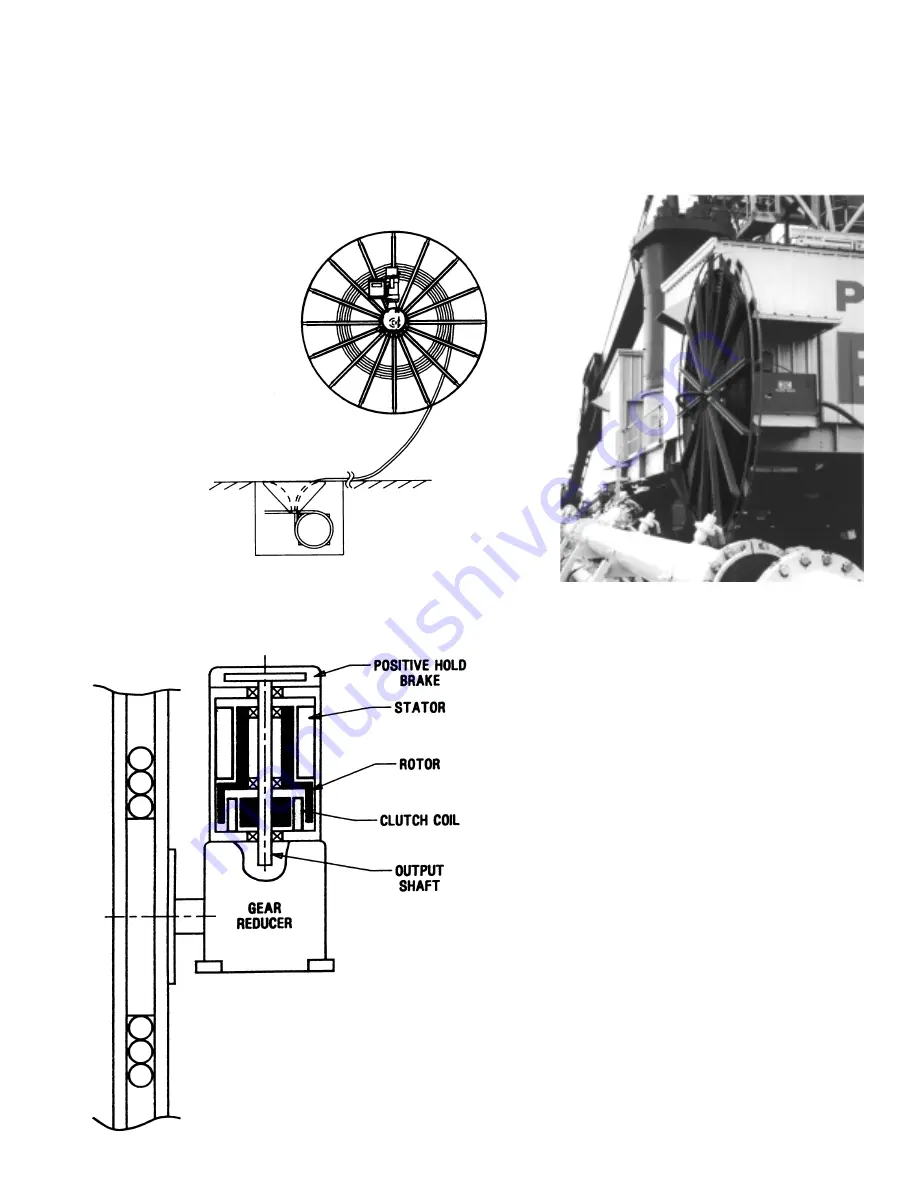

Monospiral Reels

Best Low Reel Mounting

Monospiral cable reels are designed to stack cable in a single, multiple-layer vertical configuration. They are the

solution to applications involving large cables where lateral space may be limited. This narrow spool design, togeth-

er with proven VARI-MATIC drive reliability, makes monospiral reels ideal for service in any demanding environ-

ment. Monospiral reels are available for low, medium or high speed requirements. The monospiral design allows the

reel itself to act as a cable guide. Separate guides may be installed. Each monospiral reel is custom designed using

information that you supply regarding your specific application and environment.

About the Vari-Matic

®

Drive

VARI-MATIC FUNCTION

The Gleason VARI-MATIC drive provides a

reliable solution to the challenge of retrieving

and unwinding long lengths of valuable cable at

the demanding cycle rates of today’s

advanced machinery.

The VARI-MATIC drive consists of an eddy-

current clutch fitted with a standard squirrel

cage electric motor. This drive assembly will

withstand 100% stall and requires virtually

NO MAINTENANCE.

When energized, the VARI-MATIC drive pro-

vides a constant tension to the spool and cable

for as long as the machine is in motion. When

the machine is shut off and the VARI-MATIC

drive is de-energized, a reliable mechanical

brake holds the cable spool in place, preventing

unwinding of the cable.

The VARI-MATIC drive includes a controller

in a custom designed waterproof enclosure. All

necessary adjustments for the specific operation

are completed at the factory. Field adjustments

to suit application changes are easily accom-

plished without special equipment or personnel.

Typical Level Winding Reel

Level Winding reels provide the maximum in cable handling relia-

bility. Due to size of the drum and other components required to

achieve this reliability, proper location of the reel is very impor-

tant. Minimum cable bending is the goal at both the reel and the

anchor point. Gleason will be happy to provide assistance on your

request for specific application details.

Roller Guide Assemblies

Cable rollers guide assemblies are critical for

the proper management of cable being paid out

and retrieved in today’s demanding applica-

tions. Special attention has been given to

Gleason’s roller guide designs to insure the

optimum in efficiency and reliability at each

installation. Assemblies are matched to the

specific cable diameter and weight and

installed to suit the most demanding machine

speed and travel limits.

Typical Roller Guide Assembly

Low mounted Monospiral

Reel & terminal

Typical ship loader

installation (right)

Typical Level Winding Reel

and Turnover Anchor