Page 33

COMMISSIONING

INSTALLATION

These Instructions should be placed along with the component manufacturers

instructions in the pocket provided on the rear of the front panel. The front panel

should then be refitted.

Important Do’s and Don’ts

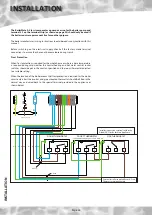

1. DO check the incoming mains water pressure and flow rate are adequate. (The

preferred range of mains pressure is 2-3bar).

2. DO check that all connections are in accordance with the labelling on the thermal

store.

3. DO adjust the ballvalve so that the water level in the F & E cistern when the

system is cold is correct and does not overflow when the whole of the system is

at maximum temperature.

4. DO make sure that there is adequate clearance above the F & E cistern to service

the ballvalve.

5. DO ensure that the range rated appliances are set at the highest output and the

boiler thermostat is set to maximum for all boilers.

6. DO ensure that the water level in the F & E cistern is at least 250mm above the

highest point on the radiator circuit or the highest point of the system.

7. DO check that the F & E cistern is not more than 6m above the base of the

BoilerMate appliance.

8. DO insulate any exposed pipework in the BoilerMate cupboard.

9. DO plumb the overflow/warning pipe in a 20mm internal diameter pipe material

which is suitable for use with a heating F & E cistern, in accordance with BS

5449 (such as copper) and ensure it has a continuous fall and discharges in a

conspicuous external position.

10. DO check the pump settings:

a. The boiler pump should be set to give a temperature difference across the

boiler of 8°C or less.

b. The heating pump should be set to give a temperature difference across the

flow and return of not more than 11°C.

c. Please note - the pumps are preset on maximum speed (3). If you wish to alter

the settings of either the primary or the space heating pumps, please refer to

the information provided by the pump manufacturer opposite.

11. DO ensure that the bypass valve for the heating system (if fitted) is set correctly.

12. DON’T use a combined feed and vent on BoilerMate installations.

13. DON’T use a BoilerMate on a sealed primary i.e. closed system.

14. DON’T use pipe smaller than 28mm between the boiler and the BoilerMate when

the boiler rating exceeds 20kW (about 68,000 Btu/h).

15. DON’T use dipped flow and return between the boiler and the BoilerMate unless

the boiler is fitted with an overheat thermostat. If necessary check with the

suppliers of the boiler.

16. DON’T place any clothing or other combustible materials against or on top of

this appliance.

Toggling the settings of UPM3

When you switch on the pump, it runs with

the factory pre-setting. The display shows the

current operation status.

1. Press the button to switch to the setting

view. The LEDs show the current setting

for 2 seconds.

2. Release the button for more than 2

seconds. The user interface shows the

current performance in “operation status”.

3. Press the button for more than 2 seconds

and the pump switches to “setting

selection.” The LEDs flash and show the

current setting mode. Please note that if

the key lock is disabled, the pump will not

switch to “setting selection”. In this case,

unlock the key lock by pressing the button

for more than 10 seconds.

4. During a period of 10 seconds, press

shortly on the button and the pump

switches to the next setting.

5. To select between the settings, instantly

press the button until you find the setting

you want. If you pass a setting, you need to

continue until the setting appears again as

it is not possible to go back in the settings

menu.

6. Release the button for more than 10

seconds and the user interface switches

back to the performance view and the last

setting is stored.

7. Press the button and the display switches

to the setting view and the LEDs show the

current setting for 2 seconds.

8. Release the button for more than 2

seconds and the user interface switches

back to the performance view.

Summary of Contents for BMAS 150 OVR

Page 38: ...Page 38 APPENDIX APPENDIX B ...

Page 40: ...Page 40 APPENDIX D NOTES ...

Page 41: ...Page 41 NOTES ...