Page 9

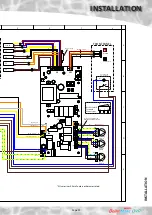

Appliance Control Board

The appliance control board (shown opposite)

has a 2 digit display and 2 push buttons which

are used to check the status of the appliance,

check and set its identity and interrogate it for

the current faults and the fault history.

The 2 digit display is controlled by 2 buttons S1

and S2 The flow chart of display modes is shown

below. Generally, each press of button S2 cycles

the display from top to bottom and each press

of button S1 cycles the display functions from

left to right.

The button S2 is also used to reset the appliance

i.e. clear the lockout errors and reset the

appliance. (Note: Appliance resetting can also

be carried out using the push button on the

front panel)

Display in Normal (Standby) Mode

In the standard/normal mode the 2 digit display

indicates the status of the appliance inputs

and outputs by switching on the appropriate

segments of the display - see page 29 for details.

Appliance Type Selection

The BoilerMate is fitted with an identity (ID)

resistor which is read by the controller for

comparison with the appliance type (code)

set on the controller. The two must match for

the controller/appliance to function. Therefore

if either the appliance code setting or the ID

resistor is wrong, the appliance will shut down

safely and flag the error code until the fault

is rectified. The controller codes and the ID

resistor values for the BoilerMate are 01 and 1K5

respectively. The procedure for checking and

setting the appliance code on the controller is

described below.

• The appliance selection menu (A0 ... A9) on the

controller is hidden. It is only possible to get to

the appliance selection using the reset button

(Left hand, S2) on the main board.

• When going from the show ‘ locking error’ to

show ‘blocking error’ menu (see opposite), do

not release the button but hold it for 10 seconds.

The display will change from ‘c’ to ‘A’. At this stage

the push button (S2) can be released.

• The appliance type can now be selected by

using right hand push button, S1, e.g. for this

appliance A01.

Press the reset button, S2, to accept the setting.

If the selected appliance code does not match

with the ID resistor fitted to the appliance, then,

an error ‘33’ will be displayed.

TECHNIC

AL

D

AT

A

DESIGN

Tank_middle

16

8

9

1

T_overh_2

T_dhw_in

ID_resistor

T_overh_1

Tank_bot

T_dhw_out

Push button

Ext_led_k

Ext_se_1

PC Connector

Reset

button

Enter

button

Main processor

FLIP jumper

J9

J31

J30

SEND_TO_GAS

VSS

GASV_IN

220_0

WD_RECEIVE

VSS

SAFETY

220_1

J29

DIV_OUT_2

220-0

DIV_OUT_1

220_0

EL_HEAT_OUT

BOIL_HEAT_DEM

OVERHEAT

220_0

BOIL_HEAT_DEM

CH_P_MOD

CH_P_L

CH_P_L

CH_P_PE

BOIL_P_PE

BOILER_P_MOD

BOIL_P_L

BOIL_P_N

DHW_P_PE

DHW_P_MOD

DHW_P_L

DHW_P_N

220_1

220_PE

220_0

220_PE

220_1

220_0

CH_ON_IN

220_0

220_1

SWL_IN

DHW_ON_IN

220_INPUT

J3

J33

J32

J34

J28

J5

S2 S1

APPLIANCE CONTROL BOARD

Figure 5

2 DIGIT ACB BOARD DISPLAY FLOW CHART

Press S2

Press S2

Press S2

Press S2

Press S2

Press

S1

Press

S1

Press

S1

Press

S1

Appliance

type

Press

S1

Press

S1

Press

S1

Press

S1

Fault code indicator

block outs

Press

S1

Press

S1

Press

S1

Press

S1

Fault code indicator

lock outs

Press

S1

Press

S1

Press

S1

Press

S1

Control set-point

reading

Press

S1

Press

S1

Press

S1

Press

S1

Sensor temperature

reading

Normal - standby state

Indicate system status

S2

S1

Figure 6

Summary of Contents for BMAS 150 OVR

Page 38: ...Page 38 APPENDIX APPENDIX B ...

Page 40: ...Page 40 APPENDIX D NOTES ...

Page 41: ...Page 41 NOTES ...